CNC Copper Busbar Bending Machine - HQ400 Series

Product Overview

Product: CNC Copper Busbar Bending Machine

Model: HQ400-1200B / HQ400-2000B

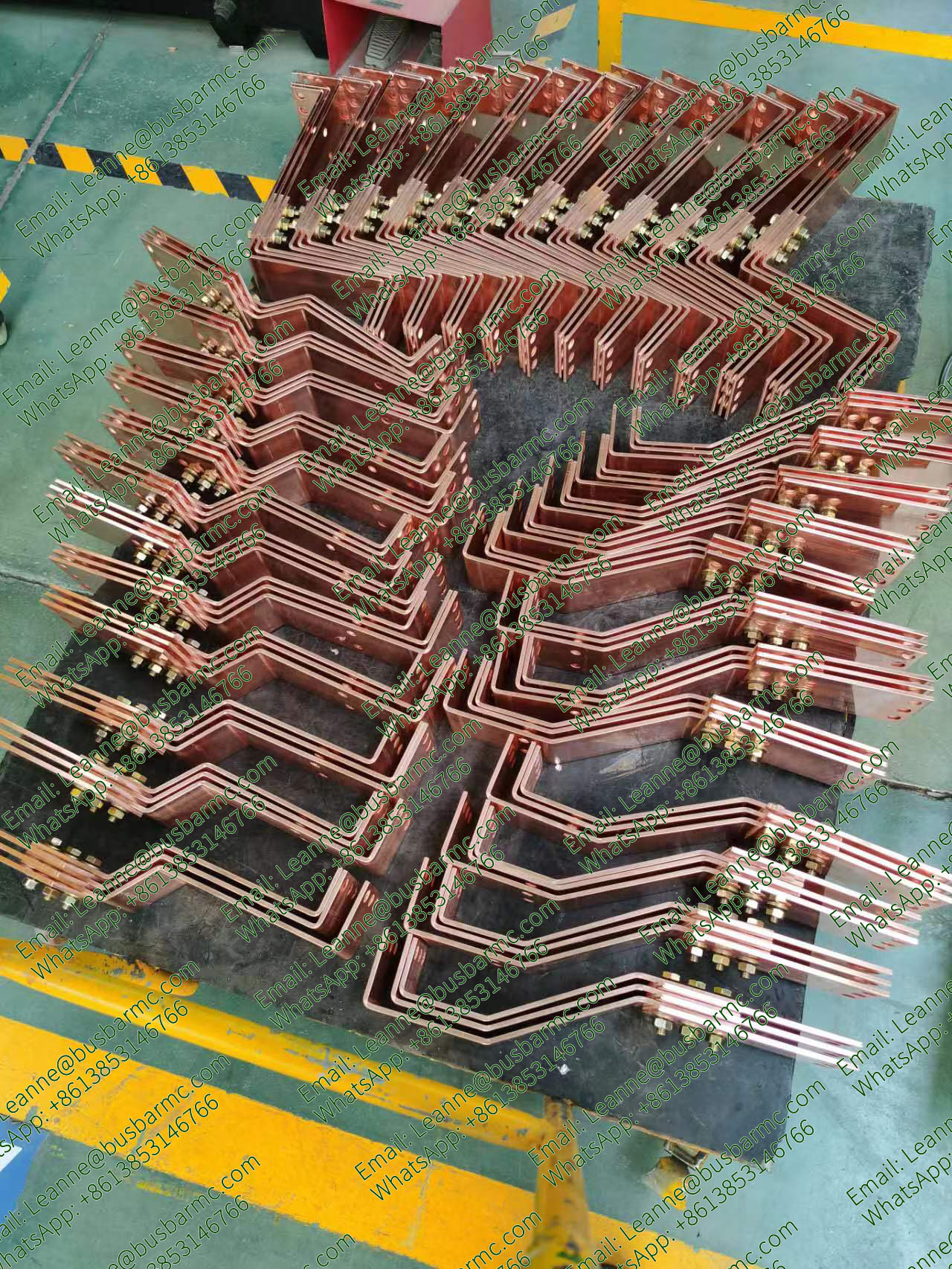

Main Function: Copper bar & Aluminum bar bending, U-bend, Stand up bending

Complete Main Features

Fully Servo Motor Drive System

Adopts fully servo motor power drive with high output pressure, transmission stability, and accurate positioning. Compatible with HQ600-SP series CNC busbar punching and shearing machine. Programming software can expand bending diagrams, generate punching/shearing codes, and import computer processing codes.Advanced "Closed Bending" Structure

HQ400-B structure features "closed bending" design with simple structure, balanced and reasonable force distribution, and greatly enhanced mechanical strength compared to first-generation open bending. Stable frame structure and welding ensure long-term use without deformation. Double linear guide rails and ball screw provide stable, noiseless operation.Intelligent Control System

Industrial computer and PLC self-programming control servo motors to complete bending angles and material blocking distance. Equipped with self-developed CAD/CAM programming software offering excellent stability, simple operation, user-friendly interface, and low control cost.Multi-Function Bending Capabilities

Powerful functions with corresponding molds for flat bending, vertical bending, and pipe bending operations on copper busbars. Capable of quick, efficient, batch production of various copper busbar bends.High Precision Performance

Easy installation and replacement of molds. Blocking accuracy: ±0.15mm, Bending accuracy: ±0.3°.Customizable Mold System

Multiple molds can be customized. Flat bending parameters for copper busbars: 15×200mm.Advanced CAD Assistant Software

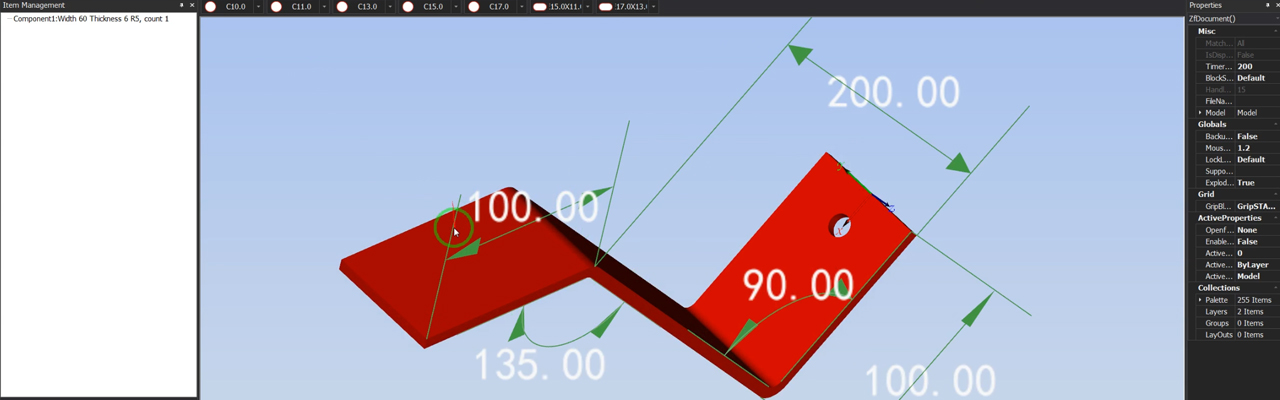

CAD assistant design software works with templates or user-created templates. One-key generation of 3D copper/aluminum busbar models. Easy operation for modifying length, angle, adding holes and positions. One-key generation of punching, shearing, and bending machining codes. Batch import of bending files with visual batch code generation. Single-line drawing to 3D model conversion. Batch calculation for copper processing optimization and raw material savings.User-Friendly Operation

Simple-to-operate CNC operating system suitable for various skill levels.

Technical Specifications Comparison

HQ400-1200B

| Nominal Pressure | 400 KN |

| Gauge Length | 1200 mm |

| Flat Bend Max | 15 × 160 mm |

| Vertical Bend Max | 12 × 120 mm |

| Gauge Accuracy | ±0.15 mm |

| Bending Accuracy | ±0.3° |

| Machine Size | 3500×1450×1850 mm |

| Weight | 3100 kg |

HQ400-2000B

| Nominal Pressure | 400 KN |

| Gauge Length | 2000 mm |

| Flat Bend Max | 15 × 200 mm |

| Vertical Bend Max | 12 × 120 mm |

| Gauge Accuracy | ±0.15 mm |

| Bending Accuracy | ±0.3° |

| Machine Size | 4300×1450×1850 mm |

| Weight | 3300 kg |

Software Capabilities

One-key generation of 3D models for copper and aluminum busbars

Template-based or custom template operation

Easy modification of length, angle, holes and positions

One-key generation of punching, shearing and bending machining codes

Batch import of bending files with visual batch code generation

Single-line drawing to 3D model conversion

Batch calculation for material optimization and cost savings