CNC Copper Busbar Punching Machine

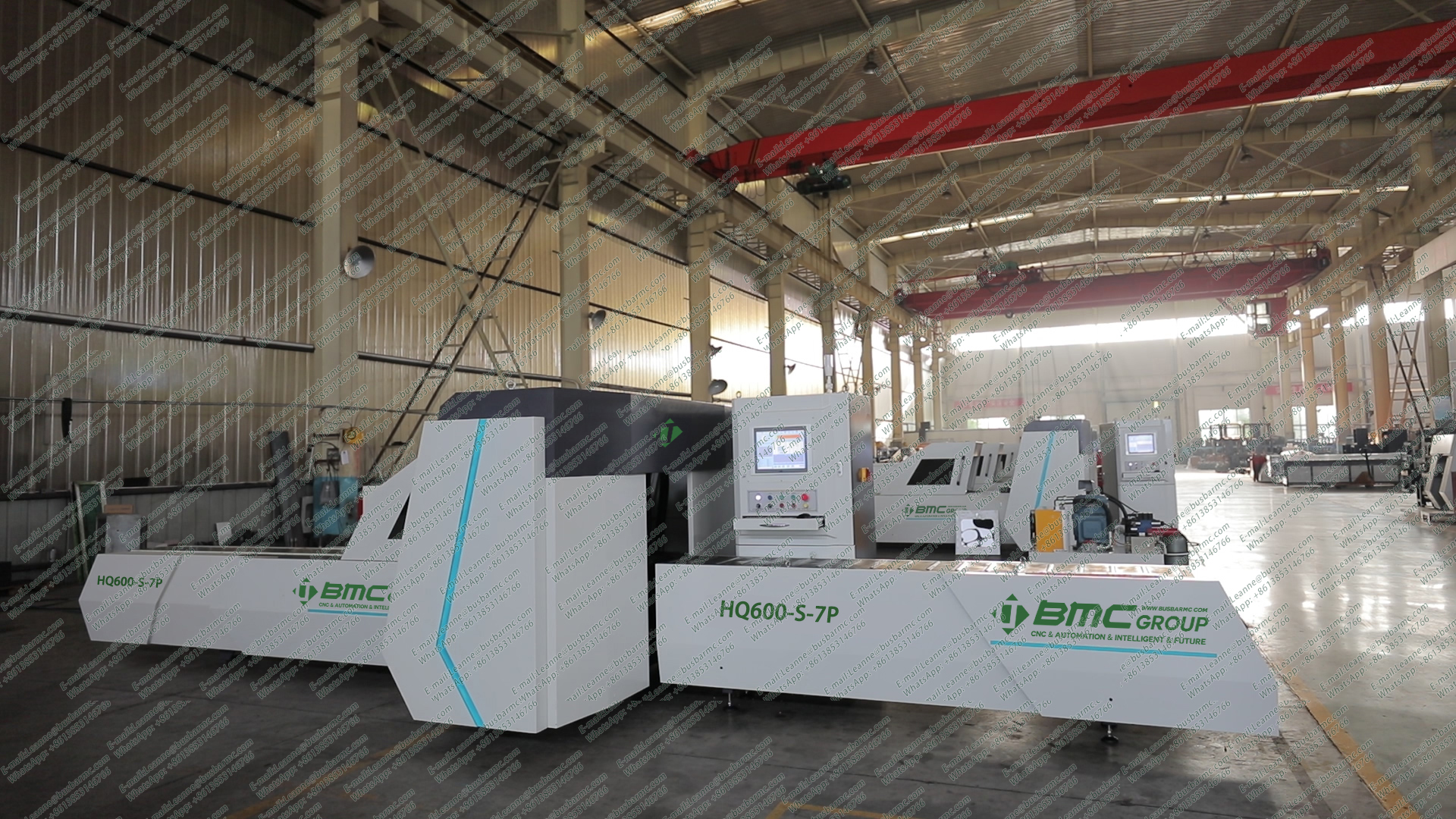

Model: HQ600-SP

Main Function

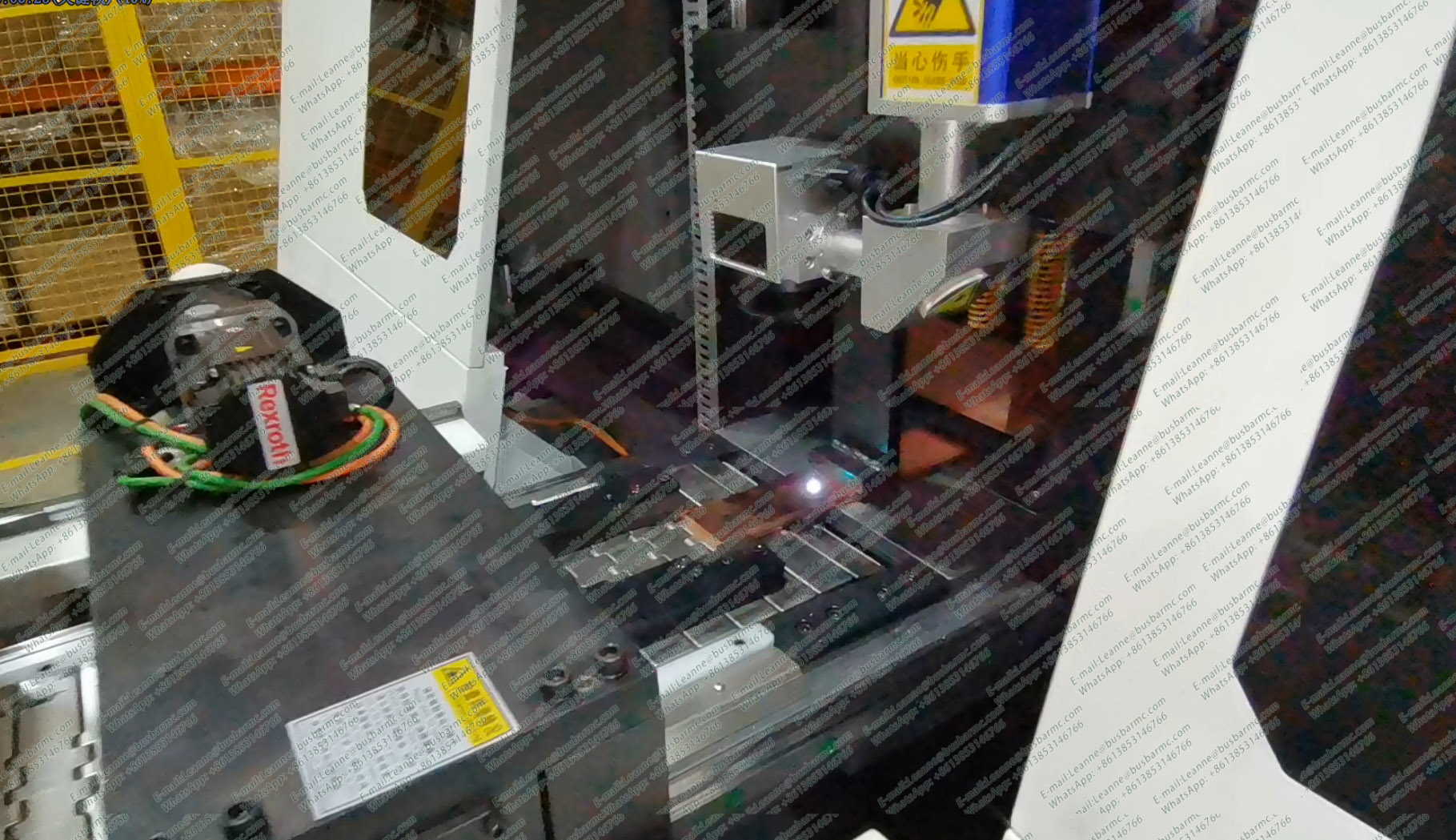

Cut, punch, chamfer, emboss (all kinds of round, square, special holes and slot type) the copper, aluminum busbar etc.

Main Features

This machine specializes in processing copper and aluminum busbars for high and low voltage systems, offering high efficiency, low energy consumption, precision, ease of use, and a modern design.

This machine features unique processing principles, a patented hydraulic cylinder system, and a daily capacity of several tons, making it the top choice for busbar processing.

It allows single clamping for long busbars, automating punching and shearing without manual intervention through automatic clamp switching. Optional 7/8-punch and 1-shear inline die sets; embossing available.

Cutting dies is a single pole type hedge Scissor, no waste after shearing.

The machine comprises a feeding table, mould base, conveying system, servo control unit, and assistant design system, delivering stable and reliable performance.

Featuring a user-friendly interface and the self-developed BMC busbar processing design system, it provides real-time monitoring of program operations.

The mould base, made of ductile iron, offers excellent wear resistance, ensuring long-term Concentricity of punching molds.

Technical Parameters

| Parameter | Model | HQ400-S-7P/8P | HQ600-S-7P/8P |

|---|---|---|---|

| Nominal Pressure | 400KN | 600KN | |

| Maximum Processing Size | 12×160mm | 15×200mm | |

| Punching Range | Φ4.3-25mm | Φ4.3-35mm | |

| Maximum Number of Molds | 8punch 1shear | 8punch 1shear 7punch +1emboss | |

| X-Axis Max Travel | 2000mm | 2000mm | |

| X-Axis Positioning Speed | 60m/min | 75m/min | |

| Y-Axis Max Travel | 860mm | 960mm | |

| Y-Axis Positioning Speed | 35m/min | 35m/min | |

| Z-Axis Max Travel | 200mm | 310mm | |

| Z-Axis Positioning Speed | 35m/min | 35m/min | |

| Punching Accuracy | ±0.2mm | ±0.2mm | |

| Positioning Accuracy | 0.10/500mm | 0.10/500mm | |

| Punching Speed | 100 times/min | 120-150 times/min | |

| Number of Control Axes | 6 Axis | 6 Axis | |

| Machine Dimensions (L×W×H) | 10500×2750×1700mm | 10500×2900×1800mm |

Optional Accessories

| Part Name | Option 1 | Option 2 |

|---|---|---|

| Main Motor | Juli | ABB |

| Hydraulic Pump | Taiwan Hydromax | American Albert |

| Solenoid Valve | Taiwan Litand | German Rexroth |

| Guides/Screws | HIWIN / TBI/PMI | HIWIN / TBI/PMI |

| Servo System | Exton | German Rexroth |

| Industrial Computer | Taiwan PanelMaster (Touch Screen) | Beijing Qiyang |

Random Accessories

8 sets of punching dies, 1 shear blade, 1 set of maintenance tools, and manuals with certificates included.