Product Information (Australian Market Edition)

Product: CNC Copper Busbar Folding Centre

Model: HQ400-1200B / HQ400-2000B (High-Precision Series)

Main Function: Copper and Aluminium Busbar Flat Bending, U-Bending, Vertical (Stand-Up) Bending for AU Switchboards

Main Features for Australian Switchgear Manufacturers

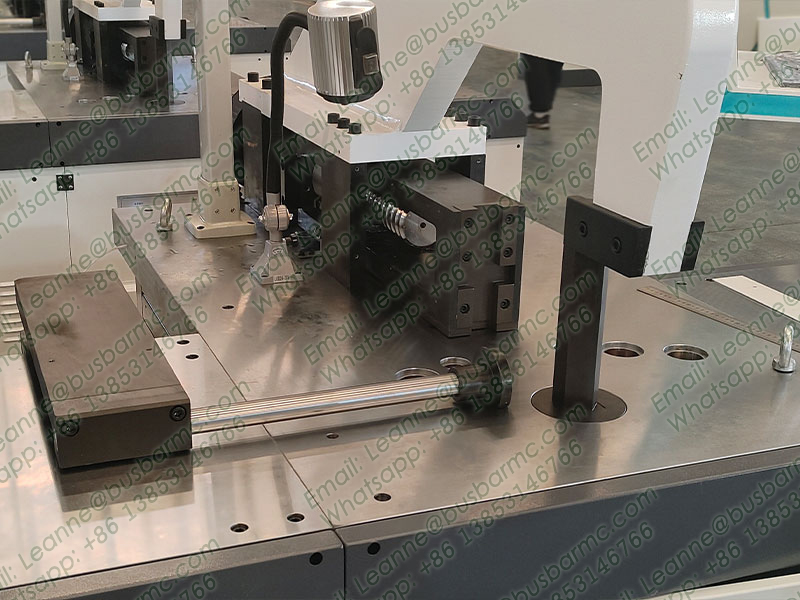

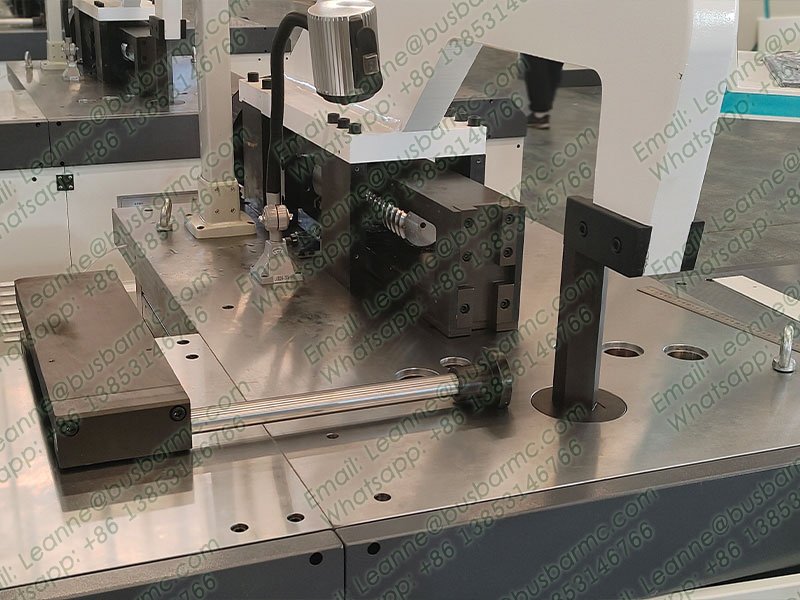

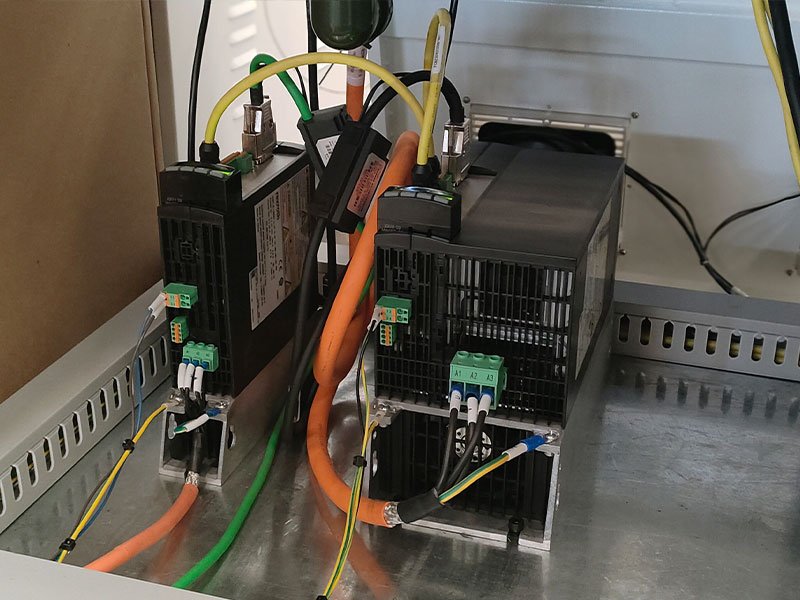

1. Fully servo motor drive system with stable transmission, high output pressure, and precision positioning for high-ampacity conductors.

2. Closed folding structure with balanced force and high mechanical strength, ensuring long-term stability without deformation in heavy-duty industrial cycles.

3. Double linear guide rails and ball screw assembly ensure smooth, low-noise operation suitable for local electrical workshops.

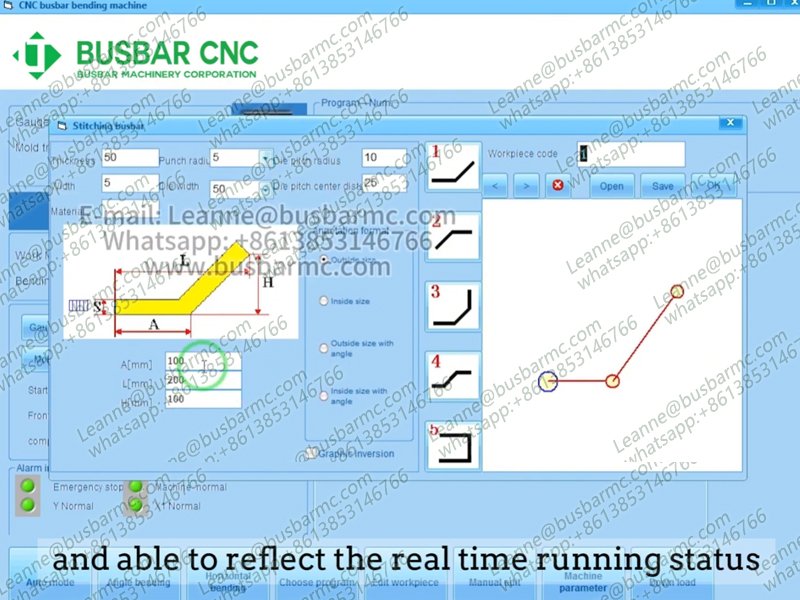

4. Industrial computer + PLC control system for precise bending angle and material positioning, meeting AS/NZS electrical standards.

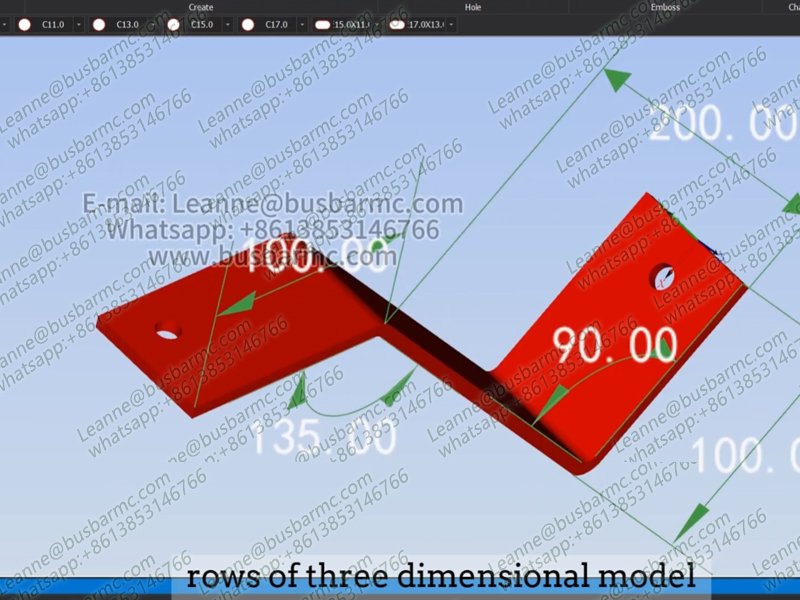

5. Equipped with self-developed CAD/CAM programming software for easy operation and fast G-code generation for complex switchgear busbars.

6. Supports flat bending, vertical bending, and offset bending with a comprehensive range of precision-machined molds.

7. Rapid mold installation and replacement system, providing stable blocking and high-repeatability bending accuracy.

8. Supports batch import of bending files (DXF/CSV) and visual generation of machining programs for high-volume electrical panel production.

Technical Parameters (AU Standards)

| Nominal Pressure | 400KN |

| Gauge Length | 1200mm (Optional 2000mm) |

| Max Horizontal Bending Size | 15 × 200mm |

| Max Vertical Bending Size | 12 × 120mm |

| Gauge Accuracy | ±0.15mm |

| Bending Accuracy | ±0.3° |

| Machine Size | 3500 × 1450 × 1850mm |

| Machine Weight | 3100kg |

Operation Video: High-Precision Busbar Folding for AU Switchboards

FAQ – CNC Copper/Aluminium Busbar Folding Centre (AU Local Support)

1. What materials can this bender process for local AU projects?

It is specifically engineered for high-conductivity copper and aluminium busbars used in Australian power distribution boards.

2. What specific folding types are supported?

The HQ400-B series supports flat (horizontal) bending, U-bending, and vertical (edge) bending, essential for compact switchgear designs.

3. How advanced is the control system?

The system utilizes a heavy-duty industrial computer and PLC control paired with a high-torque servo motor drive for elite repeatability.

4. Is the CAD/CAM software compatible with AU drafting standards?

Yes, our self-developed CAD/CAM Busbar Software is included, supporting fast programming and visual simulation to prevent material waste.

5. Can this machine integrate into a full production line?

Absolutely. It is designed to work seamlessly with our CNC Busbar Punching & Shearing Centres for a complete automated workflow.

6. Does the system support high-volume batch processing?

Yes, it supports batch import of bending schedules and visual program generation to maximize workshop throughput in Sydney, Melbourne, and beyond.

7. Can folding molds be customized for specific conductor sizes?

Yes, we provide a range of standard molds and can customize special tooling based on your specific busbar width and thickness requirements.

8. Is on-site operation training available for Australian workshops?

The CNC operating system is highly intuitive; we provide comprehensive video tutorials and remote technical support to ensure your team is proficient quickly.