HQ400-2000B CNC Copper Busbar Folding Centre | Automated Conductor Forming for Australian Switchboard & Switchgear Industry

Product Name: CNC Copper Busbar Bender

Model: HQ400-2000B (High-Capacity Series)

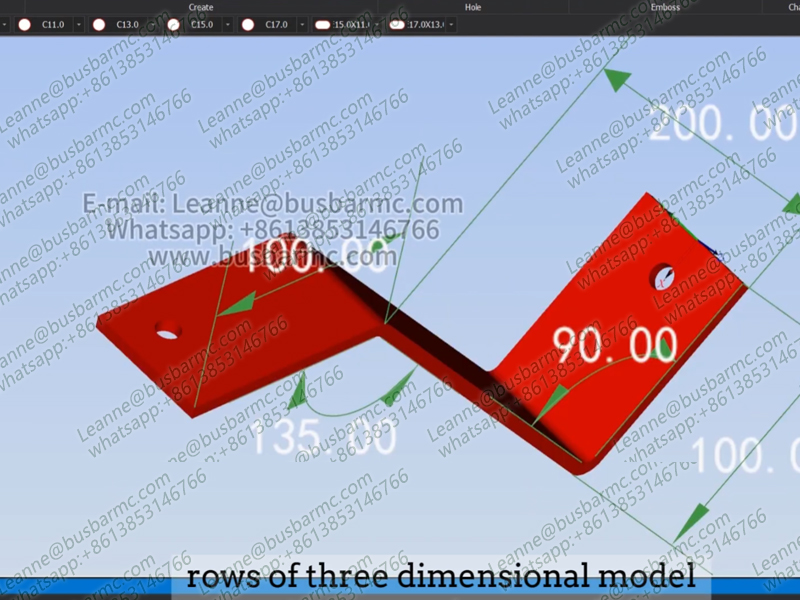

Main Function: Copper bar & Aluminium bar Flat Bending, U-bend, and Vertical (Stand-up) Folding

Widely utilised by Australian switchboard builders, power distribution cabinet manufacturers, electrical panel workshops, and transformer substation fabricators.

Main Features for the Australian Market

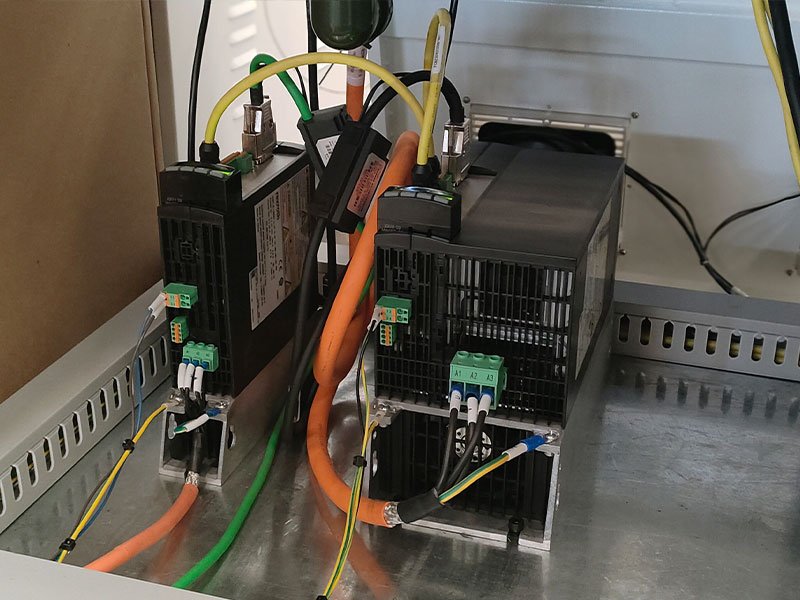

1. This machine adopts a full servo motor power drive, delivering high output pressure and stable transmission. It is designed to integrate perfectly with the HQ600-SP Series CNC Busbar Fabricator, forming a world-class automated production line.

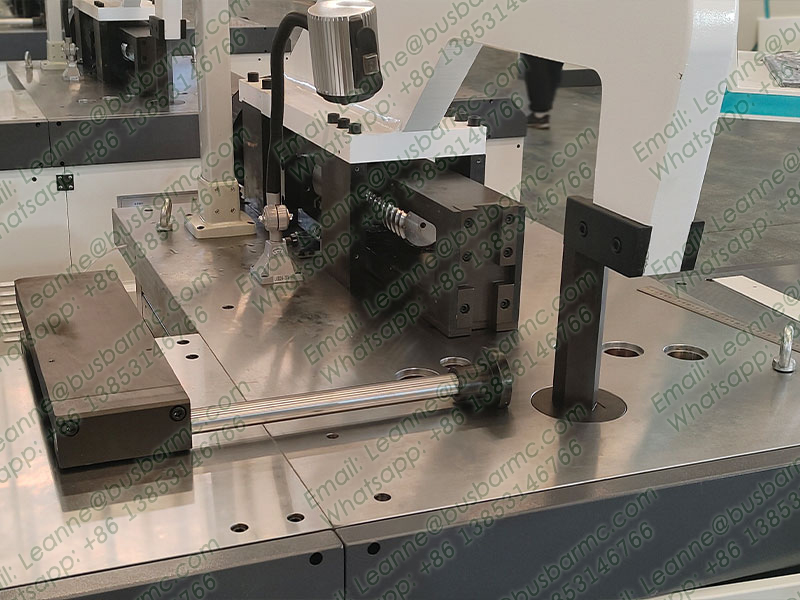

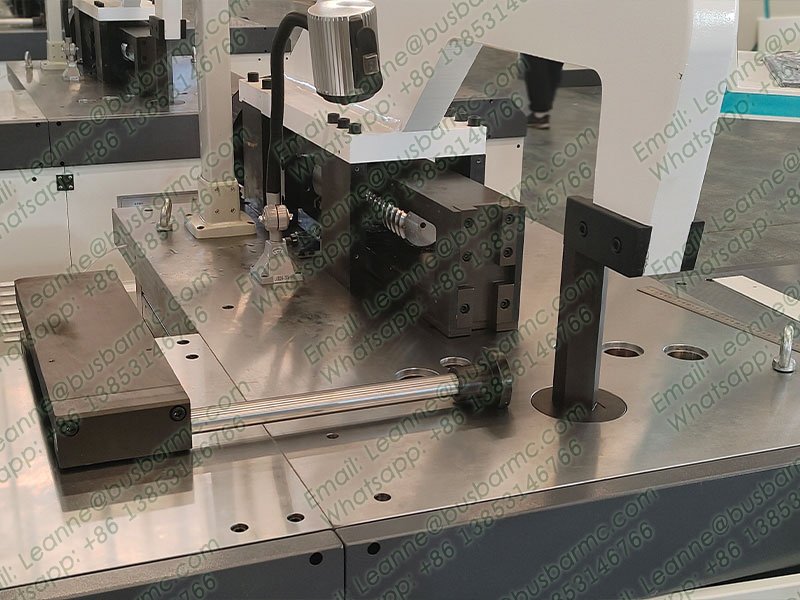

2. The HQ400-B features a closed-frame bending structure for balanced force distribution and superior mechanical strength. The heavy-duty welded frame ensures decades of use without deformation, while double linear guide rails and ball screws provide silent, smooth operation.

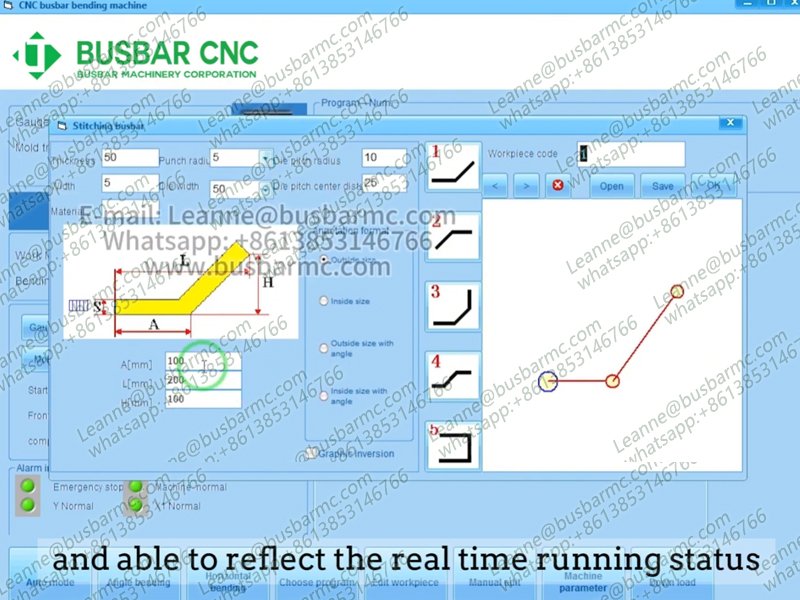

3. Industrial Computer + PLC Control System: High-precision control over the servo motor for exact folding angles and material positioning. Includes self-developed CAD/CAM software for local engineering requirements.

4. Versatile Fabrication: Supports flat bending, vertical (edge) bending, U-bending, and offset folds. Perfectly suited for high-conductivity copper and aluminium busbar fabrication.

5. Rapid Tooling System: Easy mold replacement with a gauge accuracy of ± 0.15 mm and folding accuracy of ± 0.3°, ensuring AS/NZS electrical compliance.

6. Large Capacity: Standard horizontal bending parameters handle up to 15x200mm copper bars, ideal for industrial-scale switchgear.

7. CAD/CAM Integration: Supports 3D model generation, batch DXF/CSV import, and automatic code generation. This reduces copper waste and drastically improves workshop throughput.

8. User-Friendly Interface: An intuitive CNC system designed for easy adoption by local factory workers and apprentices.

Technical Parameters (HQ400-2000B)

| Nominal Pressure | 400KN |

| Gauge Length (X-Axis) | 2000mm |

| Max Horizontal Bending Size | 15 x 200mm |

| Max Vertical Bending Size | 12 x 120mm |

| Gauge Accuracy | ±0.15mm |

| Bending Accuracy | ±0.3° |

| Machine Dimensions | 4300 x 1450 x 1850 mm |

| Total Machine Weight | 3300kg |