HQ400-1200B CNC Copper Busbar Folding Machine | Automated Conductor Bending for Australian Switchboard Manufacturers

Description:

The LT HQ400-1200B is a premium CNC busbar bender designed for the heavy-duty requirements of the Australian electrical industry. This fully automated system is engineered for precision folding of both copper and aluminium conductors used in high-voltage switchgear.

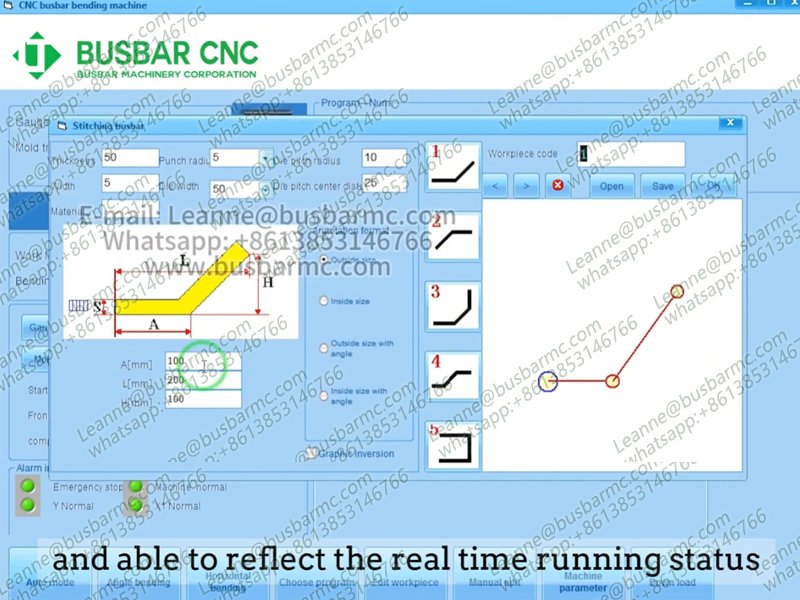

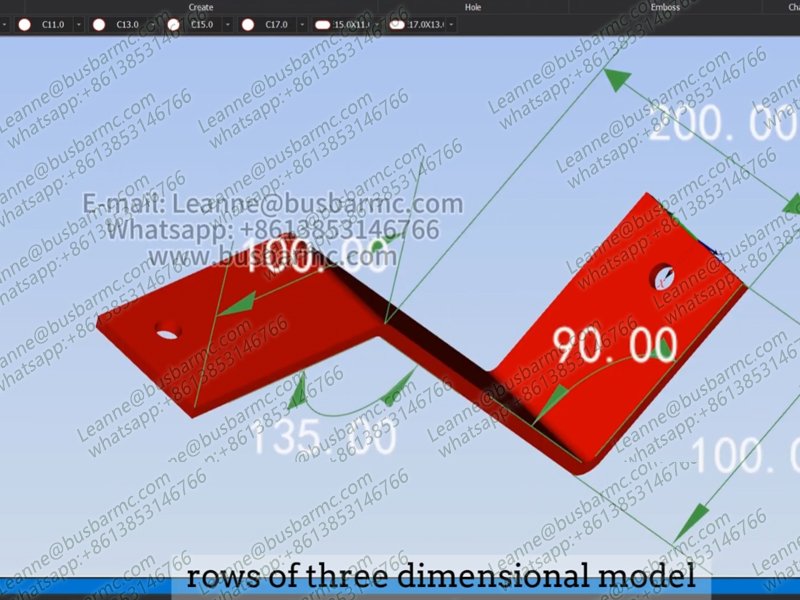

Equipped with a high-performance CNC numerical control unit and advanced CAD/CAM software, the HQ400-1200B ensures your workshop achieves elite levels of accuracy and throughput. Whether you are fabricating custom offsets or standard busbar processing solutions, this machine delivers consistent results that meet strict AS/NZS electrical standards.

The processing workflow is characterised by its high efficiency and full automation, significantly reducing manual labour costs for local switchgear fabricators. To obtain the latest busbar folding machine pricing or technical data sheets, contact our support team today.

LT CNC Busbar Folding Operation Videos:

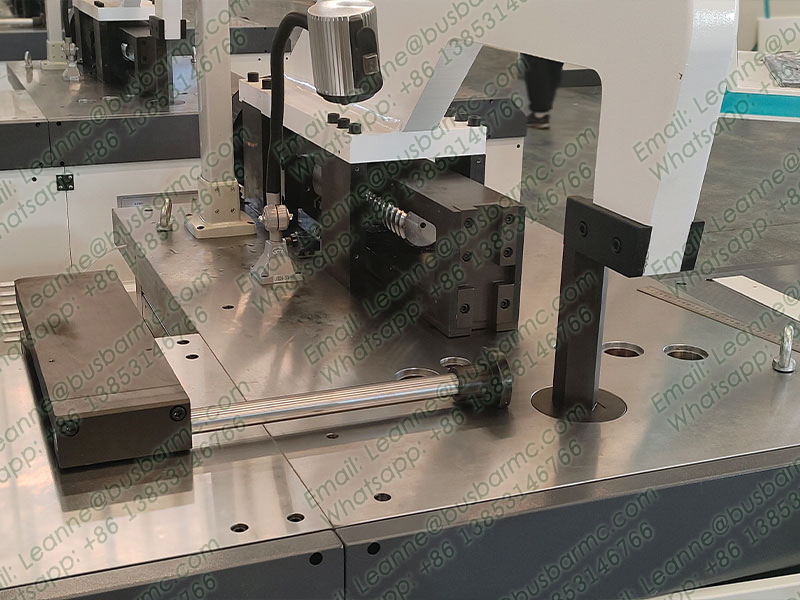

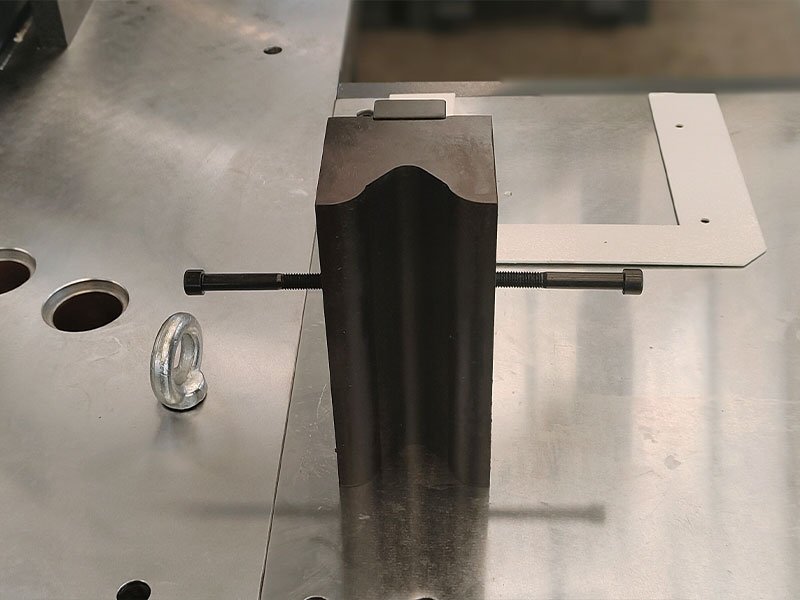

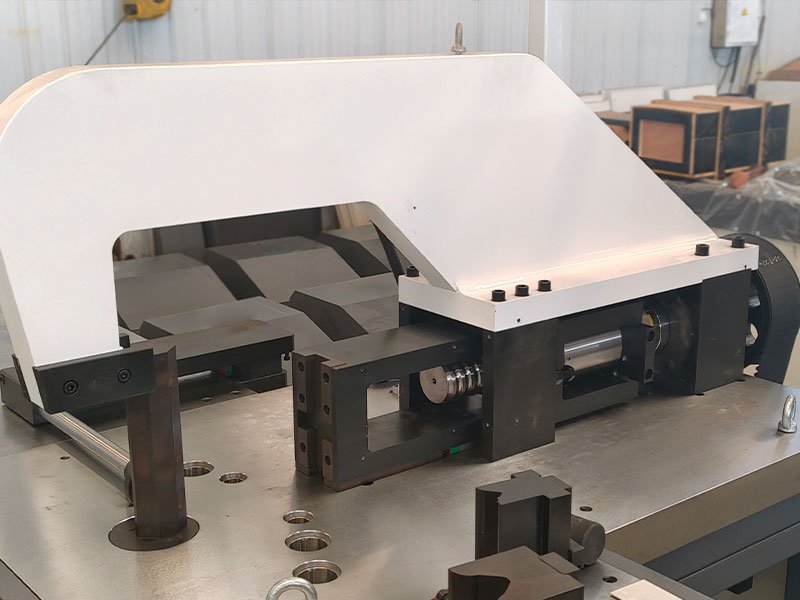

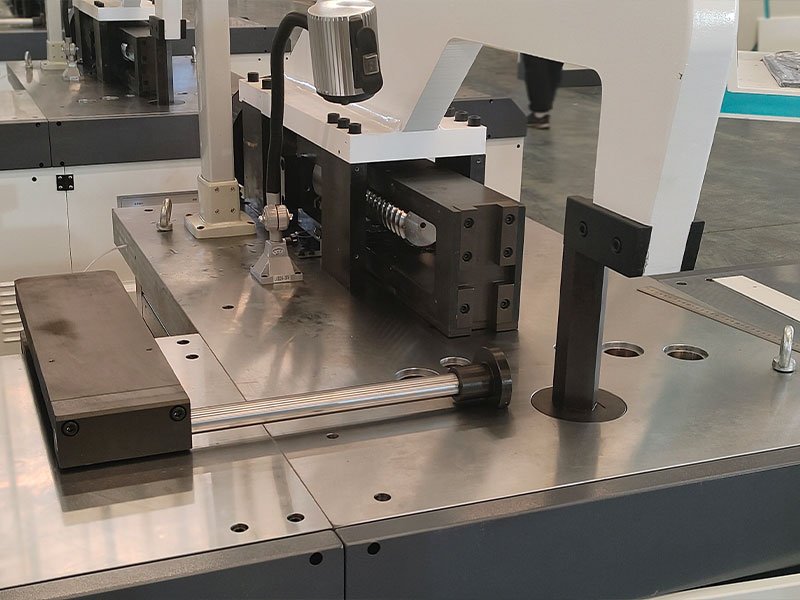

Product Gallery & Industrial Application:

HQ400-1200B CNC Busbar Folding Machine Specifications:

| Model | HQ400-1200B |

| Nominal Pressure | 400KN |

| Hydraulic Cylinder Stroke | 250mm |

| Main Motor Power | 5.5kw |

| Gauge Length | 1200mm |

| Gauge Accuracy | +/-0.15 |

| Bending Accuracy | +/-0.3° |

| Bending Head (Y Axis) Speed | Fastest 5m/min; Low: 1.25m/min |

| Max Moving Speed of Side Striker (X Axis) | 15m/min |

| Y-axis Repeat Positioning Accuracy | +/-0.02 |

| Horizontal Bending Max Size | 15mm x 160mm |

| Vertical Bending Max Size | 12mm x 120mm |

| Y-axis Servo Motor Power | 5.5kw |

| X-axis Servo Motor Power | 0.75kw |

| Machine Weight | 3100kg |

| Dimensions | 3500mm x 1450mm x 1850mm |

Core Features for the AU Electrical Sector:

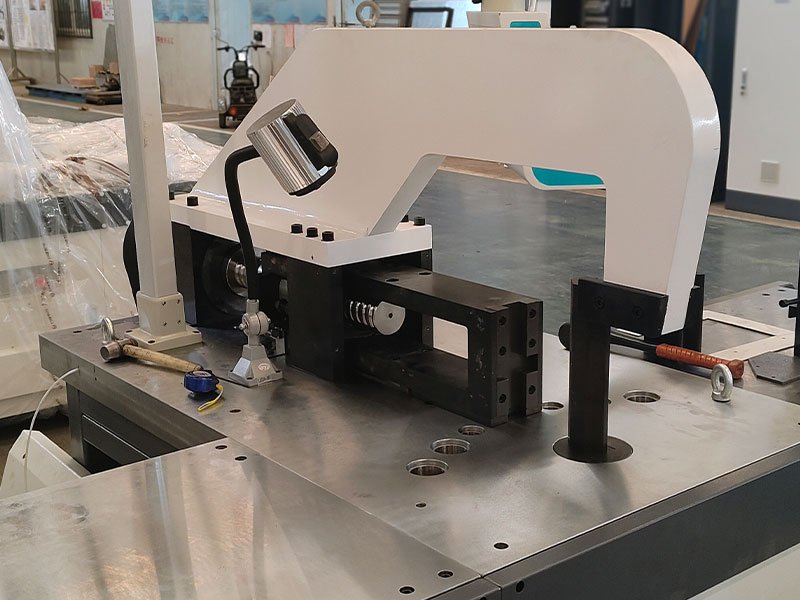

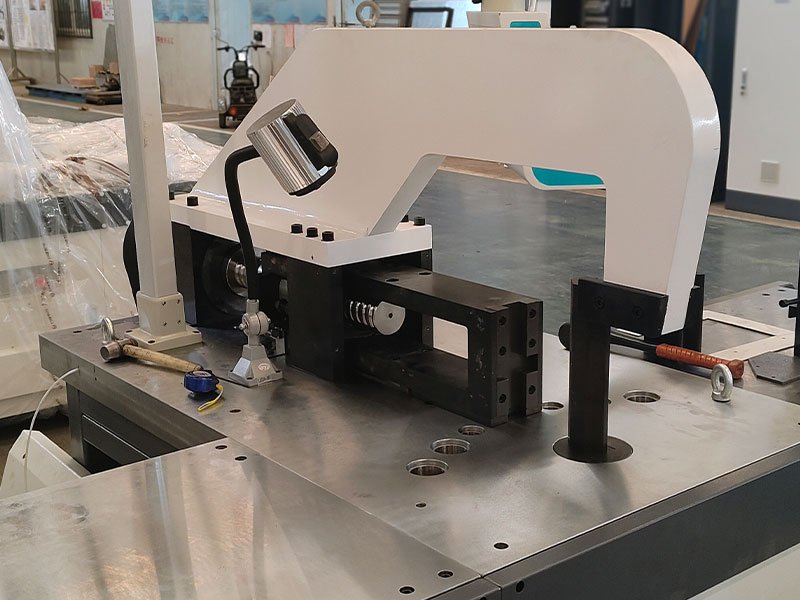

1. Heavy-Duty Closed Bending Frame: The HQ400-1200B features a robust closed-frame architecture. This design ensures uniform force distribution and superior mechanical strength compared to open-C frames, making it ideal for high-volume CNC busbar punching and shearing integration.

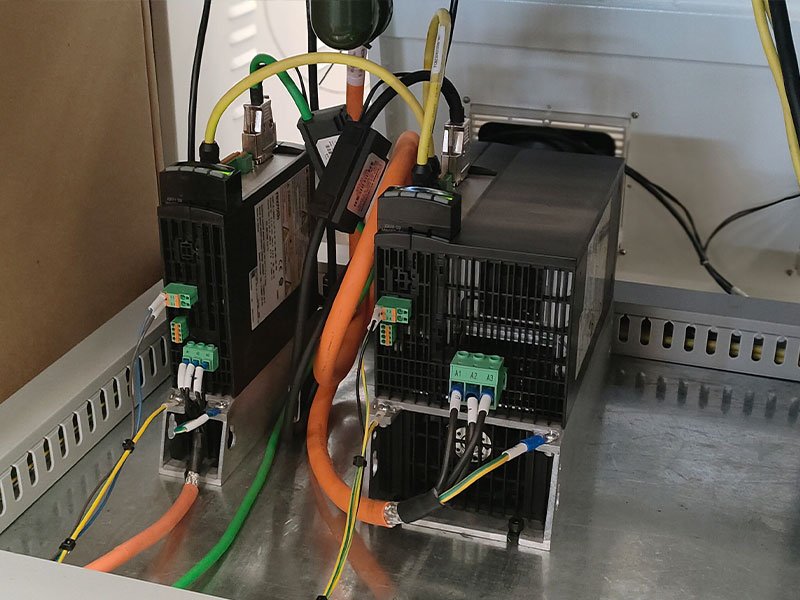

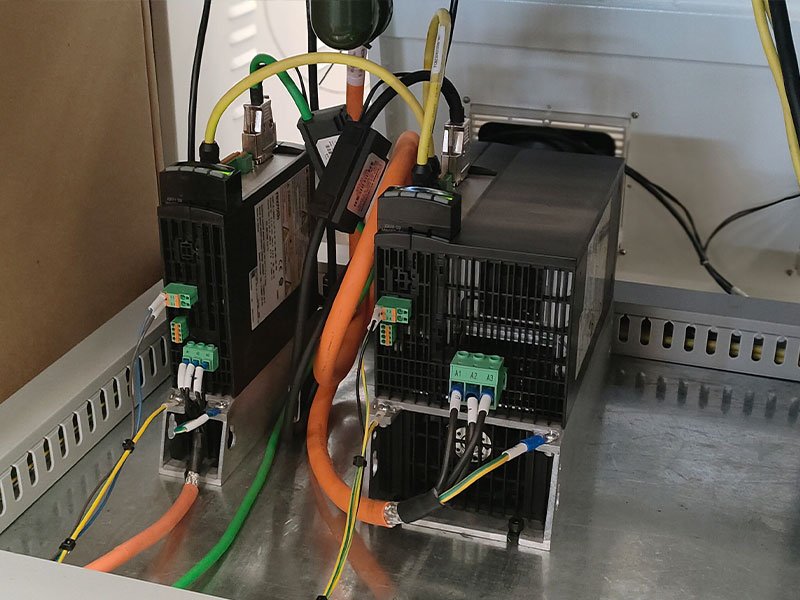

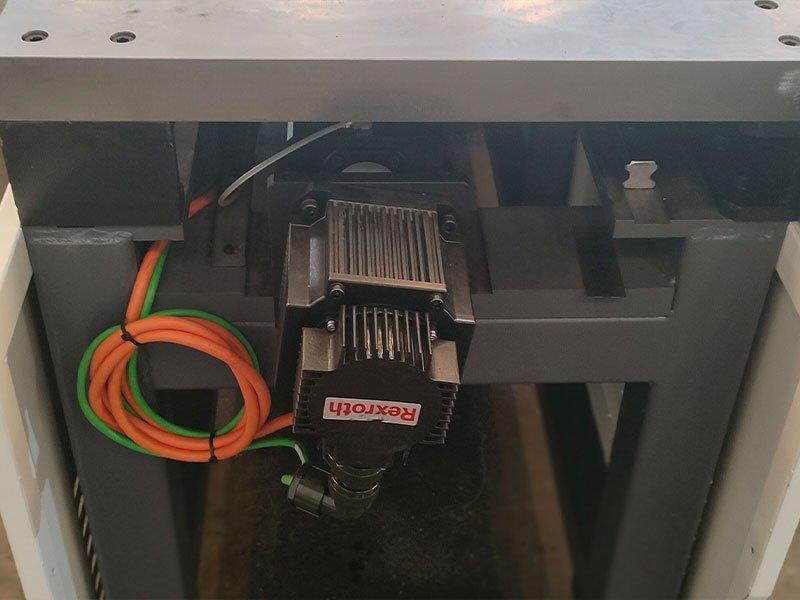

2. Precision Servo Motor Power: By utilizing a servo motor as the primary drive, the transmission remains incredibly stable. Accuracy is not affected by hydraulic oil temperature changes, providing the high repeatability required for Australian switchgear projects.

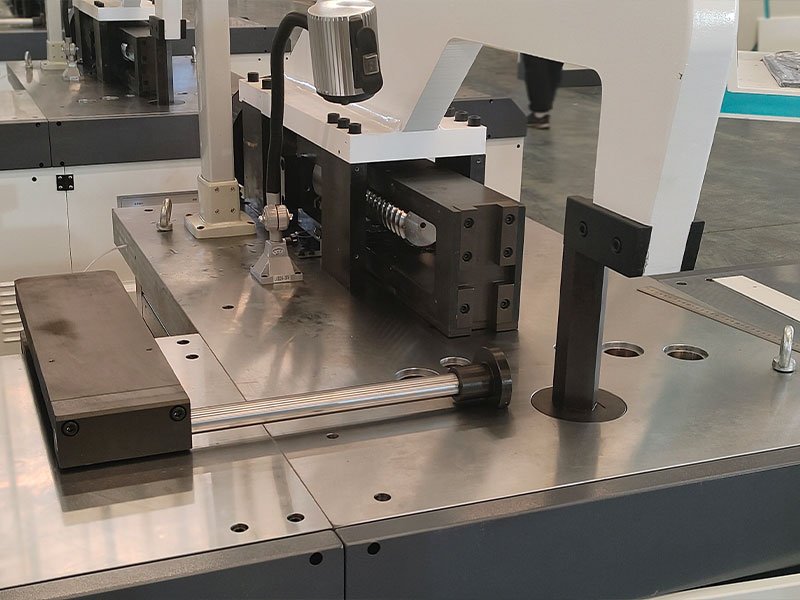

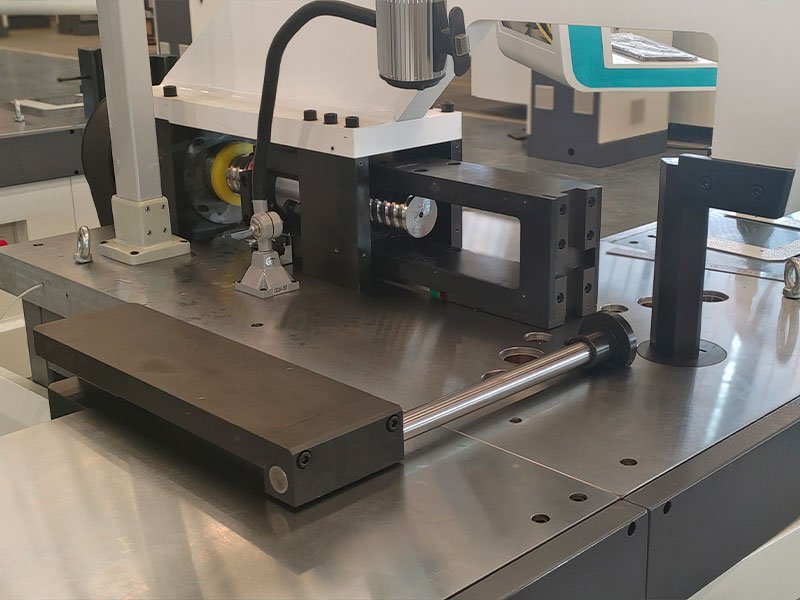

3. Intelligent CNC Stopper System: The modular back-gauge design allows for customized lengths and ensures smooth material handling for both copper and aluminium bars.

4. Integrated CAD/CAM Software Suite: The system combines an industrial CNC control unit with professional software, allowing for automatic bending code generation—perfect for complex transformer and substation components.

FAQ – HQ400-1200B CNC Copper Busbar Folding Centre:

1. Which materials are supported for local fabrication?

The machine is fully optimized for folding high-conductivity copper and aluminium busbars used in AU switchboards.

2. What are the maximum folding capacities?

Horizontal folding: up to 15mm × 160mm. Vertical (edge) folding: up to 12mm × 120mm.

3. How does the servo drive benefit my workshop?

The servo drive provides elite positioning accuracy (+/-0.02mm) and operates consistently regardless of ambient temperature, unlike traditional hydraulic systems.

4. Does it include CAD/CAM software for custom offsets?

Yes, the integrated software allows for rapid design and automatic code generation, minimizing material waste.

5. What industries in Australia typically use this model?

It is widely used by high/low voltage switchgear manufacturers, transformer plants, and power distribution cabinet builders in Sydney, Melbourne, and Brisbane.

6. Is the CNC back-gauge adjustable?

Yes, the stopper is modular and can be customized to suit your specific material lengths.

7. What is the total footprint and weight?

The machine weighs approximately 3100kg with a compact footprint of 3500mm x 1450mm x 1850mm.

Australian Industry Keywords & Hot Tags:

CNC busbar bending machine Australia, automated copper folding centre Melbourne, industrial busbar punching and shearing Sydney, copper bender for switchboards, aluminium busbar processing Perth, switchgear fabrication machinery Brisbane, AS/NZS compliant busbar tools, servo-driven copper bar bender, precision electrical conductor folding, transformer busbar manufacturing, substation copper processing, CNC electrical panel machinery, heavy-duty copper folding unit, automated conductor bending AU.

Additional Local Search Tags:

Switchboard manufacturing equipment Australia, copper busbar bender Sydney, CNC busbar machine Adelaide, electrical busbar fabrication tools,

industrial copper bar folder, high-precision busbar machinery, automatic copper processing cell,

switchgear copper folding, power distribution busbar bender, hydraulic copper bender AU.