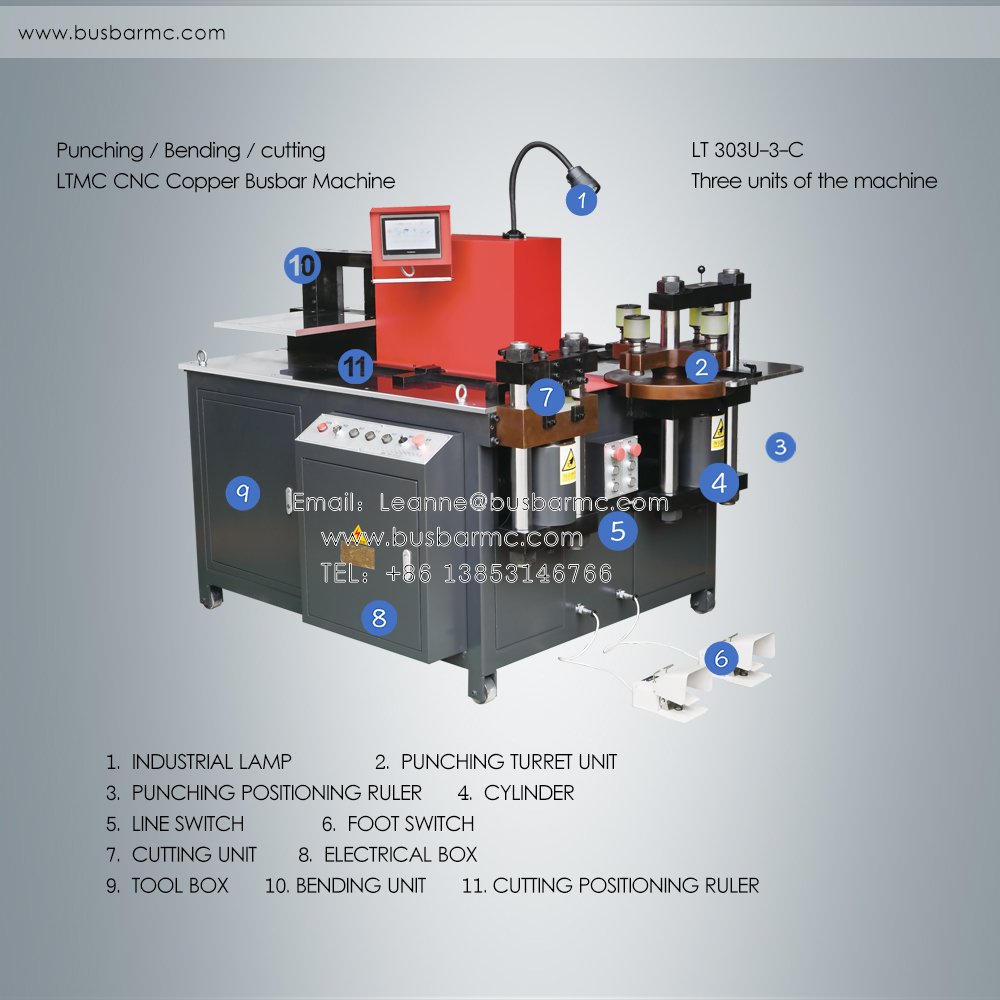

CNC Copper Processing Centre 3-in-1 Busbar Machine Product Description

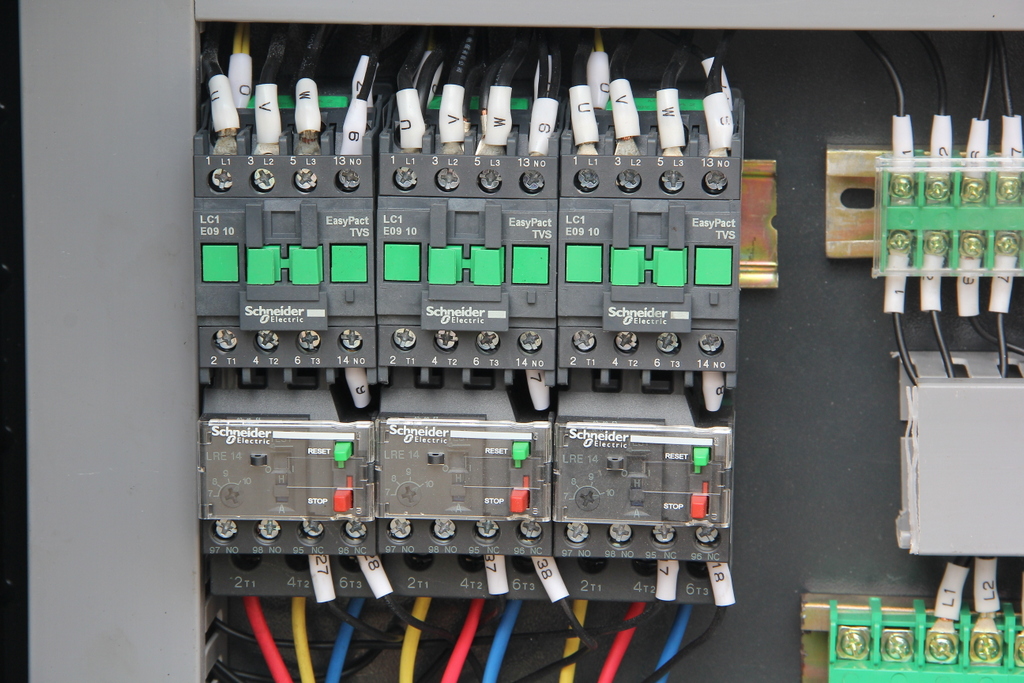

Designed for the high demands of the Australian power distribution and switchgear industry, this series of CNC busbar processing machines features three independent workstations: punching, shearing/cutting, and bending. These three units can operate simultaneously or sequentially, significantly reducing lead times for switchboard manufacturing and boosting production efficiency. The bending unit is powered by a premium German Siemens PLC control system, ensuring precision for AS/NZS compliant electrical assemblies.

Technical Parameters

Items | Model | ||

303U-3-C | 503U-3-C | 803U-3-C | |

Nominal force (kn) | 300 | 500 | 800 |

Punching dia.range (mm) | ф4.3~ф25 | ф4.3~ф30 | ф4.3~ф34 |

Max.thickness (mm) | 12 | 16 | 20 |

Max.width (mm) | 150 | 200 | 250 |

Max.shearing thickness (mm) | 12 | 16 | 20 |

Max. shearing width (mm) | 150 | 200 | 250 |

Max.horizontal bending width (mm) | 150 | 200 | 250 |

Max.Horizontal bendind thickness (mm) | 12 | 16 | 20 |

Max.vertical bending size (mm) | 10×100 | 12×120 | 12×120 |

Power (kw) | 3×4KW | 3×5.5KW | 3×5.5KW |

Bending precision (degree) | ±1° | ±1° | ±1° |

Repeat bending precision (degree) | ±0.5° | ±0.5° | ±0.5° |

First table size (mm) | 1750×1250 | 1920×1385 | 1920×1385 |

Second table size (mm) | 985×500 | 985×500 | 985×500 |

Outside dimension (mm) | 1780×1400×1300 | 1950×1560×1390 | 1950×1560×1450 |

Container size(mm) | 1870×1480×1520 | 2060×1660×1650 | 2060×1660×1650 |

Total weight(kg) | 1400KG | 1700KG | 2100KG |

Product Details

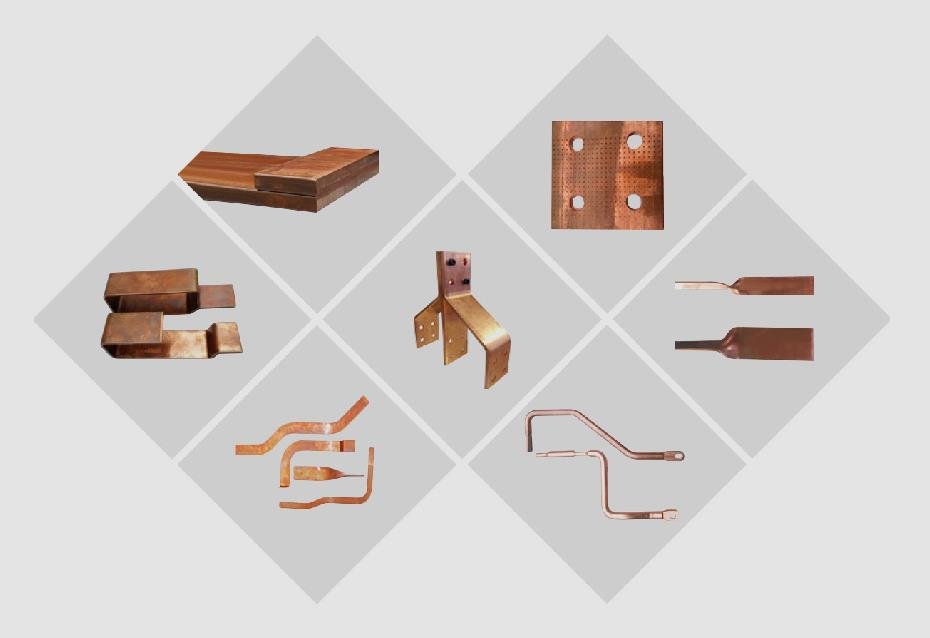

Processing Applications & Samples

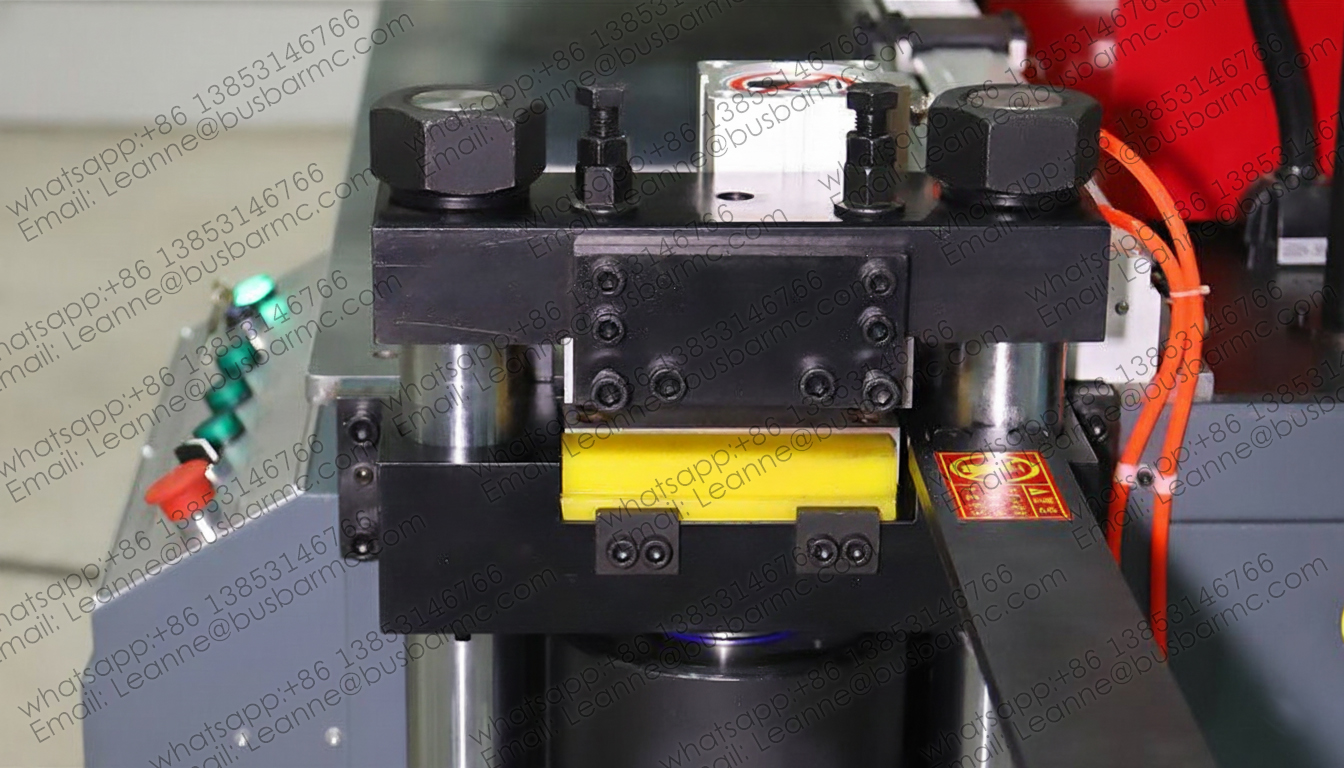

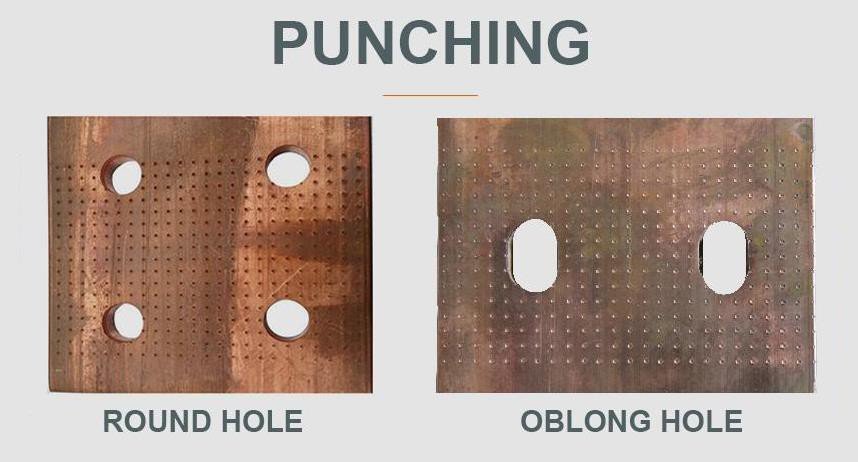

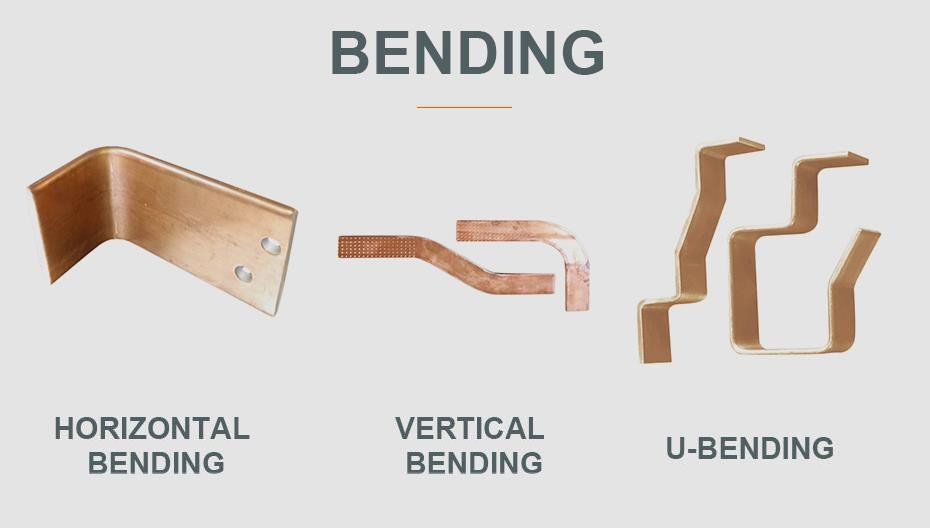

The primary function is the efficient processing of copper and aluminium busbars across various specifications. Utilizing dedicated operation units, it performs comprehensive fabrication tasks including shearing/cutting, punching (circular and oblong/slotted holes), flat/horizontal bending, vertical bending, U-bending, embossing, flat pressing, twisting, and cable connector fabrication. It is ideal for producing main switchboards (MSB), distribution boards, and link bars.

Our Factory

LTMC Company was established in 2005. With over 15 years of industry experience and resilience in the global market, we have evolved into a premier high-tech enterprise specializing in the R&D, design, manufacture, and sales of electric power equipment and CNC automation solutions for switchgear manufacturers worldwide.

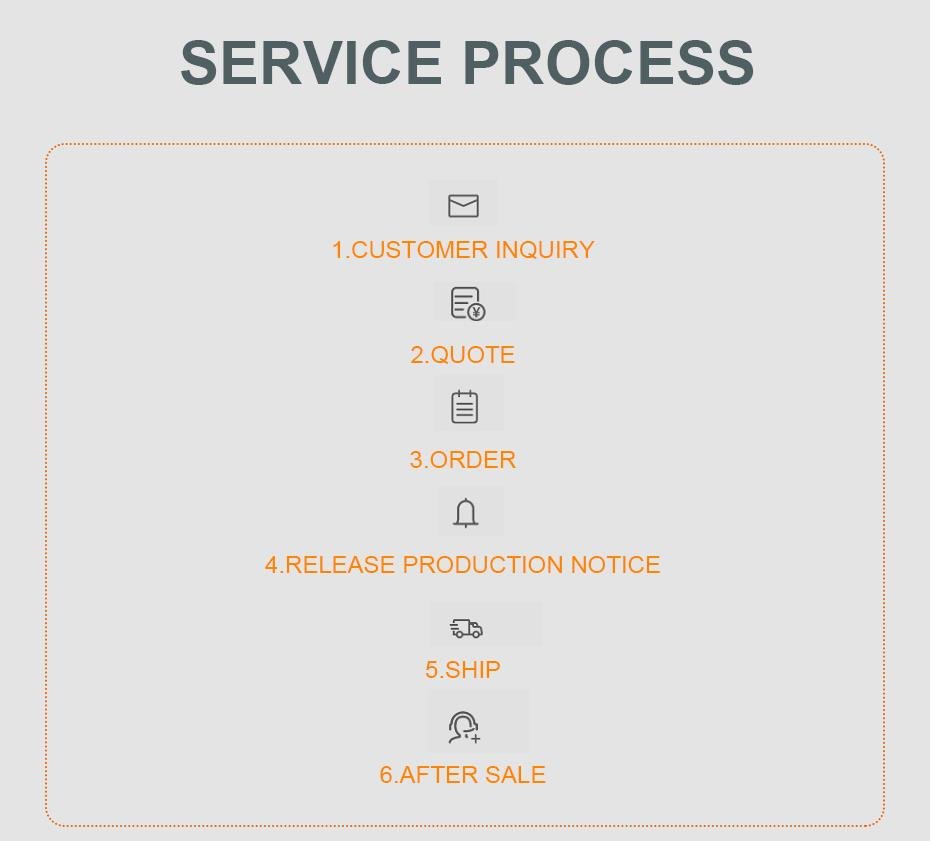

Our Service Process

1. Customer Enquiry

2. Quotation

3. Order Confirmation

4. Production Scheduling

5. Dispatch & Shipping

6. After-Sales Support

Our dedicated after-sales engineering team conducts regular follow-up visits and remote support to gather your valuable feedback, ensuring continuous improvement in our machine quality and service standards for the Australian market.

Packaging & Delivery

We utilize export-grade waterproofing plastic film for internal wrapping and robust wooden cases for external packaging to ensure seaworthy transportation to Australian ports.

Our Certifications

Hot Tags: CNC busbar machine Australia, 3 in 1 busbar processing centre, copper busbar bender, aluminium busbar punching, switchboard manufacturing equipment, busbar cutting machine, CNC hydraulic bending machine, copper link bar machine, electrical switchgear tools, busduct fabrication, China busbar machine supplier, busbar machine price, heavy duty busbar machine.

LT Busbar Machine Videos:

803U-3-C 3-in-1 Busbar Processing Centre FAQ

Q1: What is the primary application of the 803U-3-C 3-in-1 Busbar Machine?

A1: The 803U-3-C is a comprehensive CNC busbar processing centre integrating punching, shearing/cutting, and bending units. It is engineered to efficiently process copper and aluminium busbars for switchboard builders, performing tasks like flat/horizontal bending, vertical bending, U-bending, embossing, twisting, and cable connector fabrication.

Q2: Can the 803U-3-C operate multiple stations simultaneously?

A2: Yes, the three units (punch, cut, bend) can be operated simultaneously or sequentially. This multitasking capability significantly reduces processing time and boosts production throughput for busy electrical workshops.

Q3: Which control system does the bending unit utilize?

A3: The bending unit is driven by a German Siemens PLC system, guaranteeing high precision and reliability essential for meeting Australian electrical standards.

Q4: What material types can be processed?

A4: It is designed to handle both copper and aluminium busbars across a wide range of specifications commonly used in power distribution.

Q5: How is the machine packed for export to Australia?

A5: We ensure safe transit by wrapping the machine in waterproof plastic film and securing it within robust wooden crates, suitable for long-distance sea freight.

Q6: Do you provide after-sales support?

A6: Yes, LTMC provides comprehensive after-sales service. Our engineers conduct regular follow-ups to ensure your machine operates at peak performance and to address any technical queries.

Q7: Who is the manufacturer of the 803U-3-C?

A7: The machine is manufactured by LTMC, a leading high-tech enterprise established in 2005, specializing in R&D and manufacturing of CNC automation equipment for the global electrical power industry.

Related Australian Industry Keywords:

Electrical switchboard manufacturing, Power distribution boards, Main Switchboards (MSB), Motor Control Centres (MCC), Aluminium busbar fabrication, Copper link bars, Neutral bars, Earth bars, CNC hydraulic busbar processor, Switchgear assembly tools, Busduct systems, Electrical enclosure fabrication, Busbar bending and punching, Hydraulic copper cutting, Flat bar processing, AS/NZS 61439 compliance tools, Electrical substation equipment, Power rail processing, Heavy duty busbar bender, Multi-station busbar machine, Copper punching dies, Busbar bending tooling, Mobile busbar machine, Workshop machinery Australia, Sheet metal working machinery, Electrical fit-out tools, Switchboard builders equipment, Hydraulic ironworker for busbar.