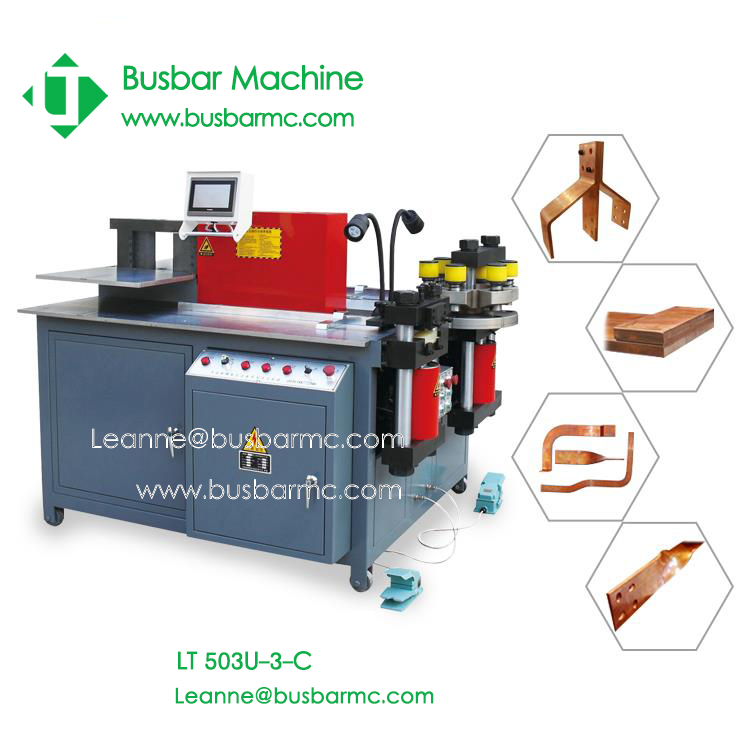

Product Overview:

Product Details

Model: LTMC-503U-3-C / LTMC-303U-3-C

Power: 3×4Kw / 3×5.5Kw

Delivery time: 7-25 days

MOQ: 1 unit

Certificate: ISO9001:2000 / CE

Payment: T/T, L/C

Brand: LJMC

Origin: Jinan, China

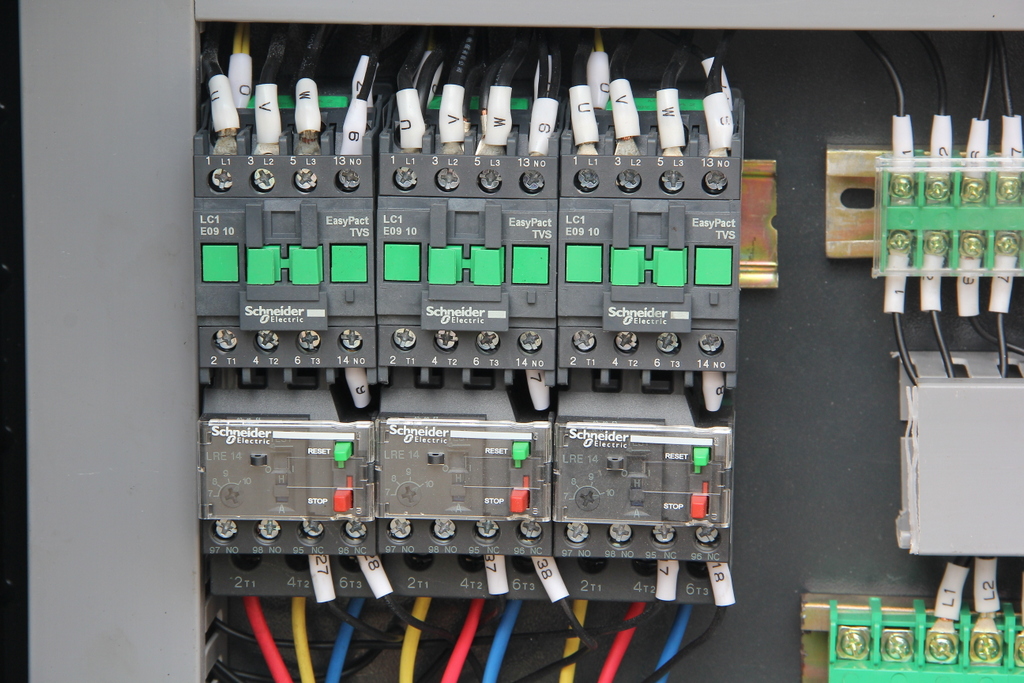

This CNC fully automatic busbar processing centre integrates three independent units: punching, shearing (cutting), and bending. Designed with three independent hydraulic systems, it allows the punching, shearing, and bending units to work simultaneously, maximising throughput for high-volume switchboard manufacturing.

The machine achieves fully automatic positioning of all three units through the seamless cooperation of servo motors, PLC control, and a user-friendly touch screen interface.

Main Features for Australian Industry:

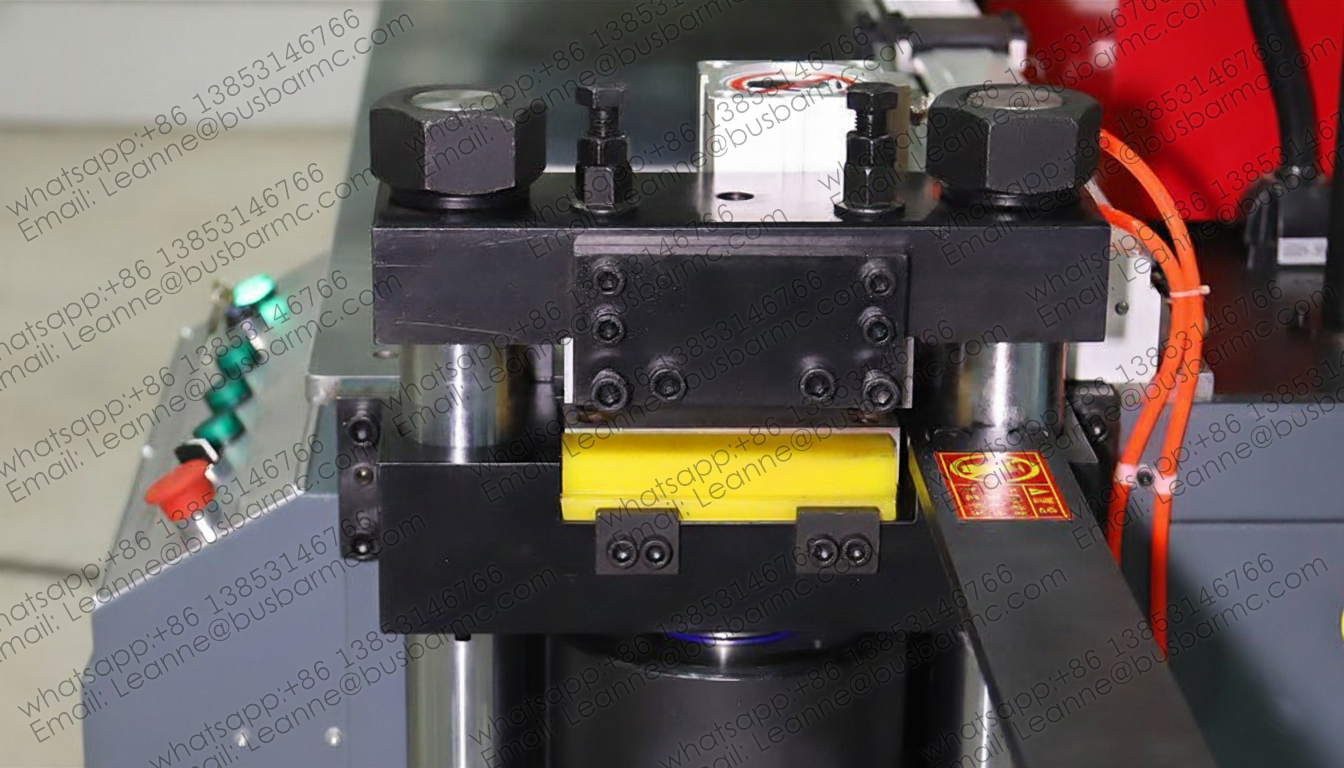

(1) The Shearing/Cutting Length is automatically controlled by a precision servo motor. The incision interface is flat, with no waste, no burrs, and no droop—ensuring high-quality results for electrical fit-outs.

(2) No Marking Required for Punching. The servo motor automatically locates punching coordinates. It supports continuous punching, punching with different apertures, coordinate input, and common template selection, making it incredibly convenient and efficient for diverse automated busbar fabrication tasks.

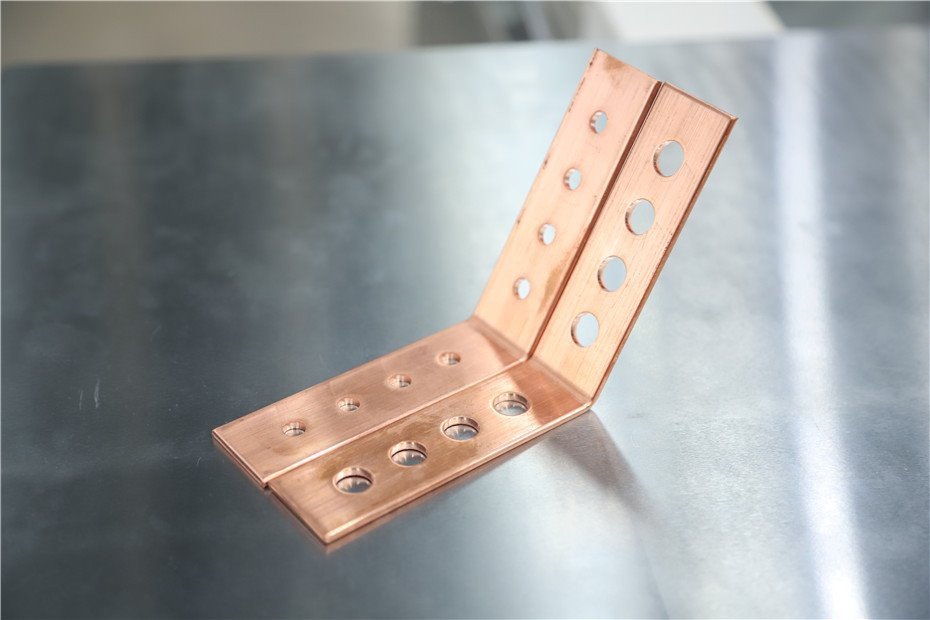

(3) The Intelligent Bending System automatically calculates the unrolling (developed) length of the copper or aluminium busbar. High-precision screw guides control the bending length. The system includes various built-in bending processing templates and supports multi-segment and multi-angle continuous bending processing.

Processing Units Display

Shearing Unit

Punching Unit

Bending Unit

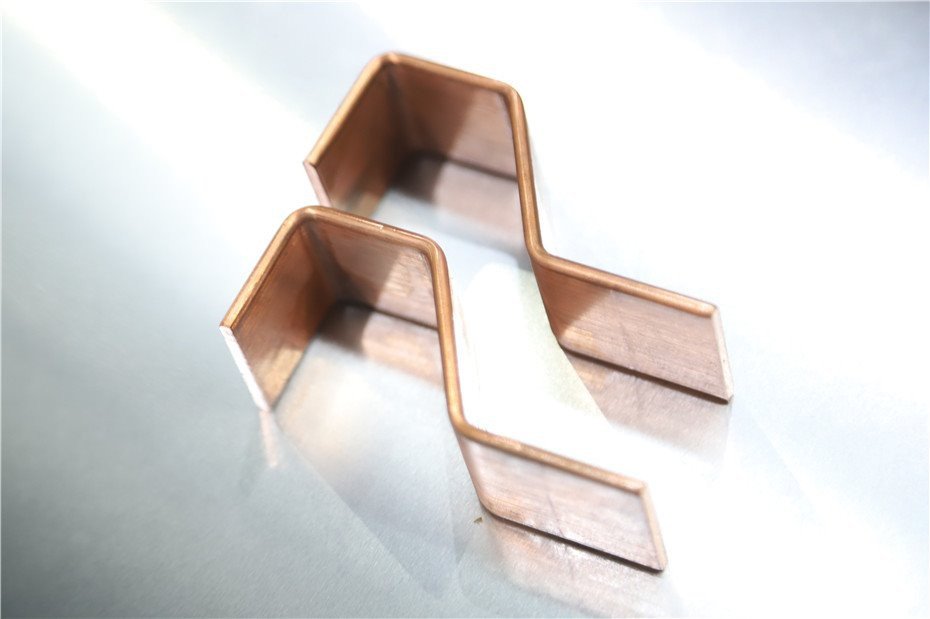

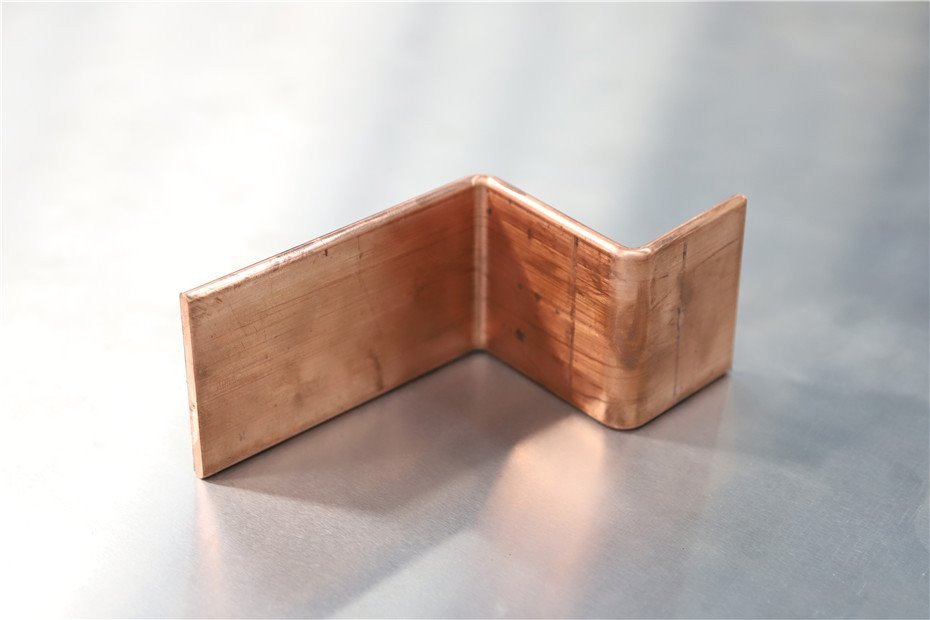

Processing Samples Display

| Item | Model | |

| LTMC-303U-3-C | LTMC-503U-3-C | |

| Nominal force (kn) | 300 | 500 |

| Punching dia. range (mm) | Φ4.3~Φ25 | Φ4.3~Φ30 |

| Max. thickness (mm) | 12 | 16 |

| Max. width (mm) | 160 | 200 |

| Number of servo axes | 4 | 4 |

| Punching Y-axis stroke (mm) | 150 | 200 |

| Punching X-axis stroke (mm) | 500 | 500 |

| Cutting X-axis stroke (mm) | 1000 | 1000 |

| Bending X-axis stroke (mm) | 500 | 500 |

| Precision of block gauge (mm) | 0.2 | 0.2 |

| Bending precision (degree) | ±1° | ±1° |

| Repeat bending precision (degree) | ±0.5 | ±0.5 |

| Power (kw) | 3×4kw | 3×5.5kw |

| Outside dimension (mm) | 1850×1650×1340 | 2015×1815×1420 |

| Total weight (kg) | 1500 | 1900 |

Hot Tags (Australia): CNC busbar processing centre, fully automatic busbar machine, auto punching shearing bending, switchboard manufacturing system, copper busbar automation, high volume busbar fabrication

Global Tags: 3-in-1 busbar machine, busbar bending machine, busbar punching machine, busbar cutting machine, CNC bending machine, cutter machine, machine bending, China suppliers, factory price.

CNC Busbar Machine Video Demo:

FAQ for LTMC-503U-3-C / 303U-3-C CNC Busbar Processing Centre

Q1: What functions does this fully automatic busbar machine provide?

A1: This CNC processing centre combines punching, shearing (cutting), and bending functions in one integrated unit. Each unit is driven by an independent hydraulic system, allowing simultaneous operation for maximum efficiency.

Q2: What materials can the machine process?

A2: It is engineered for processing copper and aluminium busbars within the rated thickness and width specifications of each model.

Q3: What is the maximum busbar size the machine can handle?

A3: Depending on the model:

LTMC-303U-3-C: Max. thickness 12 mm, Width 160 mm

LTMC-503U-3-C: Max. thickness 16 mm, Width 200 mm

Q4: Does the machine support automatic positioning?

A4: Yes. The machine utilizes high-precision servo motors, PLC control, and a touch screen interface to achieve fully automatic positioning for punching, shearing, and bending operations.

Q5: How is the shearing accuracy and surface quality?

A5: The shearing length is servo-controlled for precision. The resulting cut surface is flat, without burrs, droop, or material waste.

Q6: Do I need a template or marking for punching?

A6: No. The servo system automatically positions the punching coordinates based on your input. It supports continuous punching, mixed aperture punching, coordinate input, and template selection.

Q7: Does the machine support multi-angle or multi-segment bending?

A7: Yes. The intelligent system automatically calculates the busbar unrolling (developed) length and supports complex multi-segment and multi-angle continuous bending tasks.

Q8: How many servo axes does the machine have?

A8: Both models (LTMC-303U-3-C and LTMC-503U-3-C) are equipped with 4 servo axes for superior control.

Q9: What is the delivery time for Australia?

A9: The standard production time is 7–25 days. Shipping time to major Australian ports varies.

Q10: What certificates does the machine have?

A10: The machine is certified with ISO9001:2000 and CE standards.

Q11: What payment terms are supported?

A11: We accept T/T and L/C.

Q12: Where is the machine manufactured?

A12: The machine is manufactured in Jinan, China, by LJMC, a leader in transformer and switchboard fabrication equipment.

Australian Industry Keywords: CNC fully automatic busbar machine, auto busbar processing centre, copper busbar punching system, aluminium busbar shearing line, switchboard manufacturing automation, high volume busbar fabrication, 4-axis busbar machine, servo controlled busbar bender, intelligent busbar processing, electrical switchgear production line, heavy duty busbar equipment, automatic copper bar bending, CNC hydraulic busbar station, busbar fabrication centre Australia, multi-station busbar machine, precision busbar cutting, automated electrical workshop tools, LTMC busbar machinery, switchroom fit-out equipment, power distribution manufacturing systems.