Turret Dual-Table CNC Busbar Processing Machine

Product Description

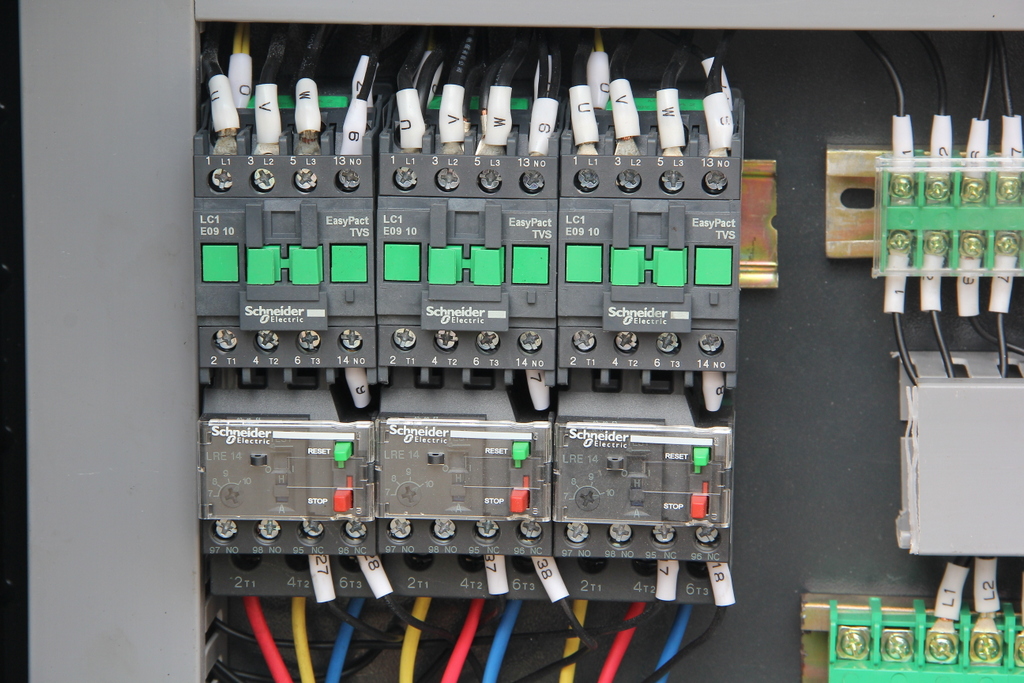

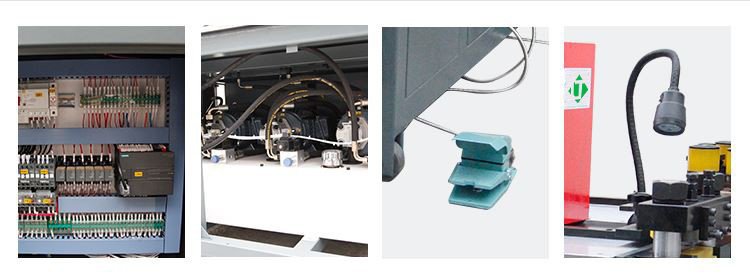

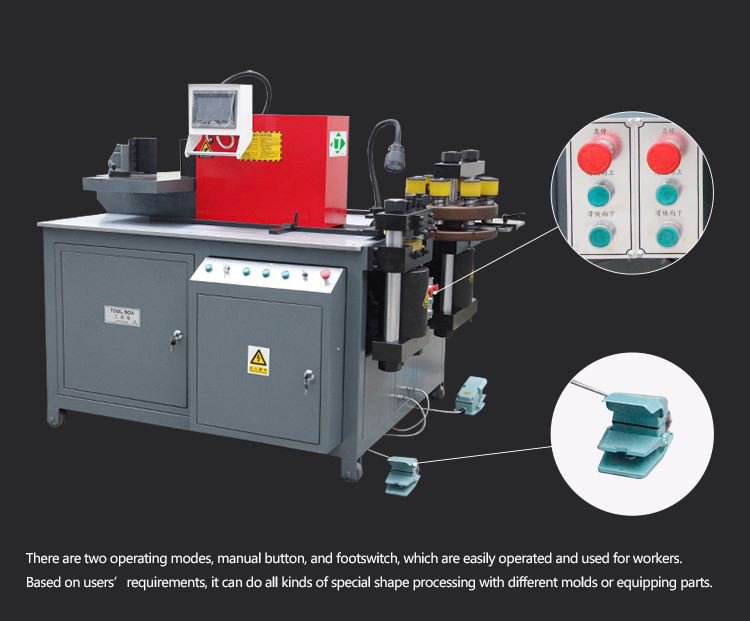

As a professional busbar machinery supplier for the Australian market, we present this advanced Turret Dual-Table CNC Busbar Processing Machine. It integrates three independent units: punching, shearing, and bending. The design allows for easy adjustment of each unit to significantly shorten processing time and improve production efficiency for switchboard manufacturers.

It is specifically engineered to process copper and aluminium busbars in various specifications. By utilising the relative operation units, operators can easily and quickly perform all kinds of fabrication tasks, such as shearing, punching (circular and oblong holes), flat/horizontal bending, vertical bending, and knurling. With interchangeable moulds, it can also handle special processing like flat pressing, embossing, cable connector forming, twisting, and pushing.

Main Characteristics for Australian Workshops

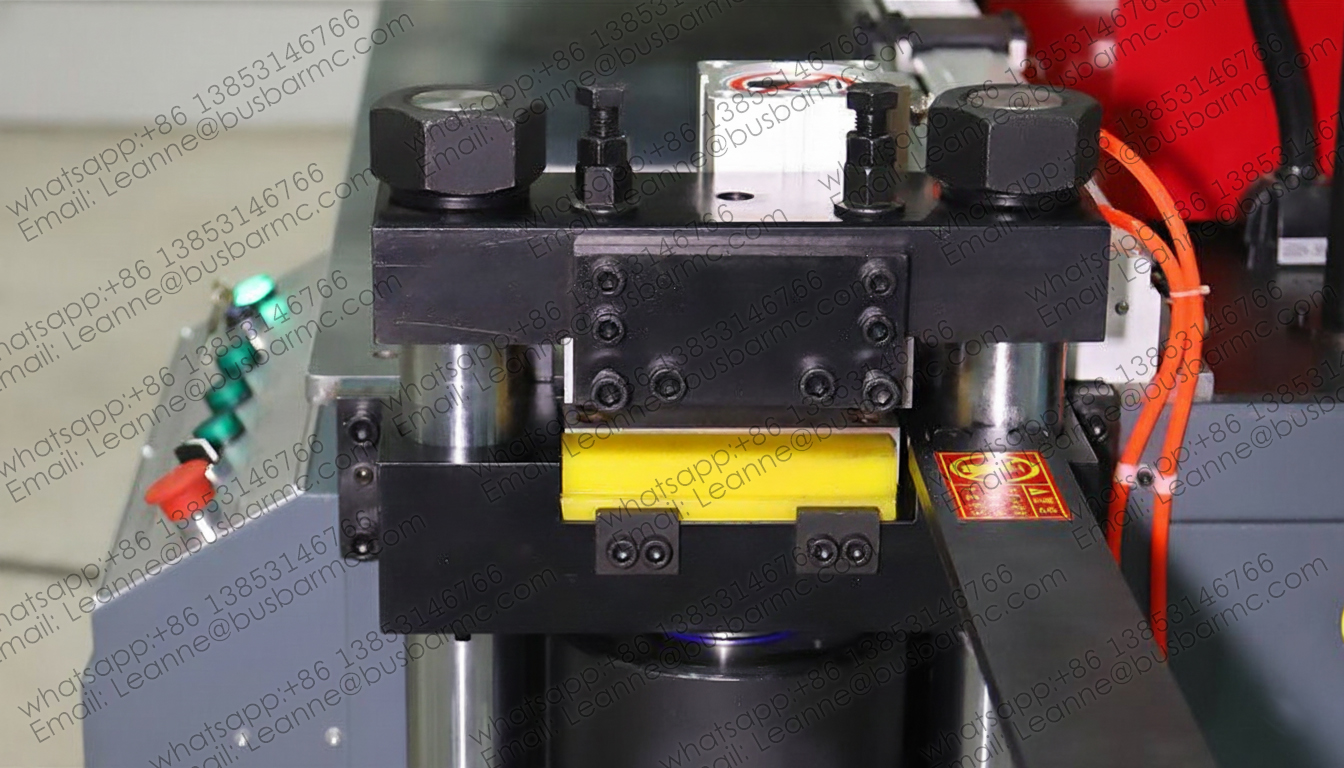

1. The Shearing Unit utilises a sharp shearing mechanism. The incision interface is flat, with no droop, no burrs, and no waste—ensuring a clean finish essential for electrical compliance.

2. The Punching Unit features a united eight-mode turret turnplate. This robust design lengthens the working life of the dies and eliminates the need to change moulds frequently, highly reducing labour intensity. It is far more efficient than traditional single-punch units often found in older workshops.

3. The Bending Station utilises a double-decker (dual-table) worktable. This is a key feature that ensures the three working stations can be operated simultaneously without any interference between long busbars. The bending station adopts an open structure, making it very convenient to position and remove processed copper bars.

4. The machine is equipped with four heavy-duty castors, making it easy to move around your workshop floor. It offers two operating modes: manual button and footswitch, which are user-friendly for operators. Based on your specific requirements, it can perform all kinds of special shape processing with different moulds or equipping parts. For those seeking even higher automation, consider our fully automatic CNC processing centres.

Processing Samples Display

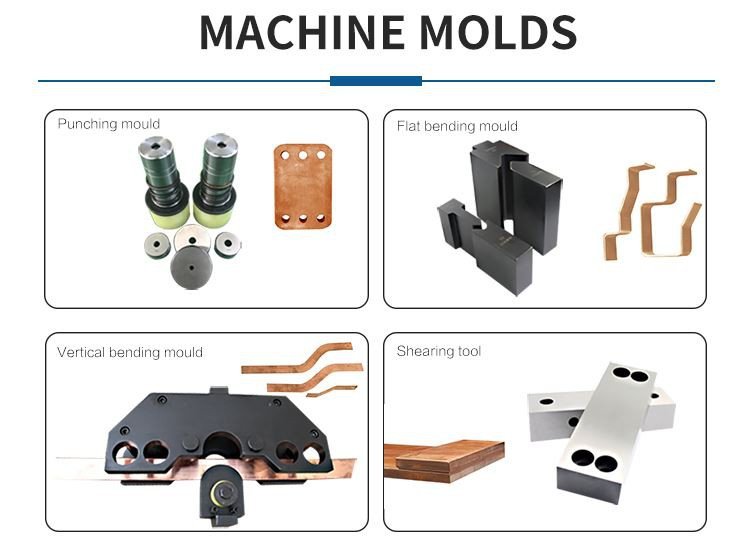

Machine Moulds & Dies

We supply a comprehensive range of versatile 3-in-1 busbar workstations tooling.

We have hole punching moulds, shearing blades, bending dies, and fully customized moulds for unique electrical applications.

LTMC Certifications

Busbar Machine Packaging and Shipping

LT Dual-Table Busbar Machine Video Demo:

Turret Dual-Table Busbar Processing Machine FAQ

1. What is a turret dual-table busbar processing machine?

This machine is a multifunctional CNC busbar processor equipped with independent punching, shearing, and bending units. The "dual-table" design allows the bending unit to operate independently from the punching/shearing units, enabling simultaneous processing of copper and aluminium busbars.

2. What operations can this machine perform?

It handles shearing, punching (round and oblong holes), flat/horizontal bending, vertical bending, knurling, embossing, flattening, cable connector forming, twisting, and customised bending with specialised moulds.

3. What are the advantages of the 8-mode turret punching unit?

The 8-mode turret turnplate eliminates the need to change dies frequently for different hole sizes. This significantly improves efficiency, extends die life, and reduces labour intensity for the operator.

4. How does the shearing unit perform?

The shearing unit adopts a sharp-shearing system (scissor type or flat blade depending on config), ensuring smooth cutting surfaces without burrs, drooping, or material waste—critical for Australian switchboard standards.

5. Why is the double-deck (dual-table) worktable important?

This design allows three stations to operate at the same time without interference, even when processing long busbars. This effectively doubles the throughput compared to single-table machines.

6. Is the machine portable?

Yes, it is equipped with four heavy-duty castors, allowing convenient movement and repositioning within your workshop.

7. How is the machine controlled?

Workers can choose between manual button control on the panel and footswitch control for hands-free operation.

8. Can it use customised moulds?

Absolutely. Based on your project requirements, we can supply special moulds for unique shapes like twisting or embossing.

9. What industries in Australia use this machine?

It is widely used in electrical switchgear manufacturing, power distribution equipment production, transformer workshops, and busbar fabrication centres across Sydney, Melbourne, and Brisbane.

10. Does it support mass production?

Yes. The combination of the turret punching structure and the dual-table design makes it highly suitable for continuous, high-volume industrial production.

Hot Tags (Australia): Turret dual-table busbar machine, CNC busbar processor Australia, hydraulic busbar bender, simultaneous busbar processing, copper aluminium busbar machine, switchboard fabrication tool

Australian Industry Keywords: Dual-table busbar machine, CNC busbar processing machine, hydraulic busbar punching bending shearing machine, 3-in-1 busbar fabrication machine, copper aluminium busbar working machine, busbar punching shearing bending machine, turret busbar punching machine, double-decker busbar processor, CNC copper busbar equipment, industrial busbar forming machine, high-efficiency busbar workstation, multi-function busbar processing equipment, electrical switchgear busbar machine, power distribution busbar fabrication equipment, busbar workshop machinery, busbar hole punching equipment, busbar cutting and bending tool, heavy-duty hydraulic busbar machine, copper busbar customization machine, aluminium busbar fabrication solution, professional busbar processing tools, programmable CNC busbar system, automatic busbar sheet metal machine, copper bar punching and shearing equipment, switchgear copper busbar production machine, electric cabinet busbar processing line, simultaneous operation busbar machine, non-interference busbar bender.