<input type="hidden" id="productID" name="productID" value="196017562"/>

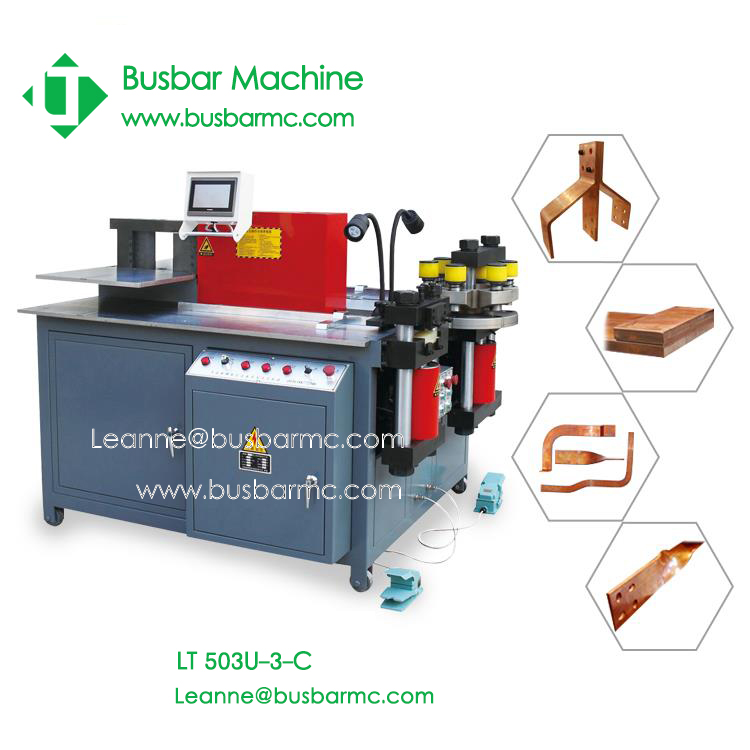

Premium 3-in-1 Copper/Aluminium Busbar Processing Machine for Switchboard Manufacturing

Product Description:

This heavy-duty **3-in-1 Copper/Aluminium Busbar Processing Machine** is specifically engineered for the Australian electrical switchgear and switchboard manufacturing industry. It integrates three independent stations: punching, shearing (cutting), and bending. Designed for efficiency and precision, each unit can be adjusted independently, significantly shortening processing time and boosting production output for electrical panel builders.

Detailed Images of Stations:

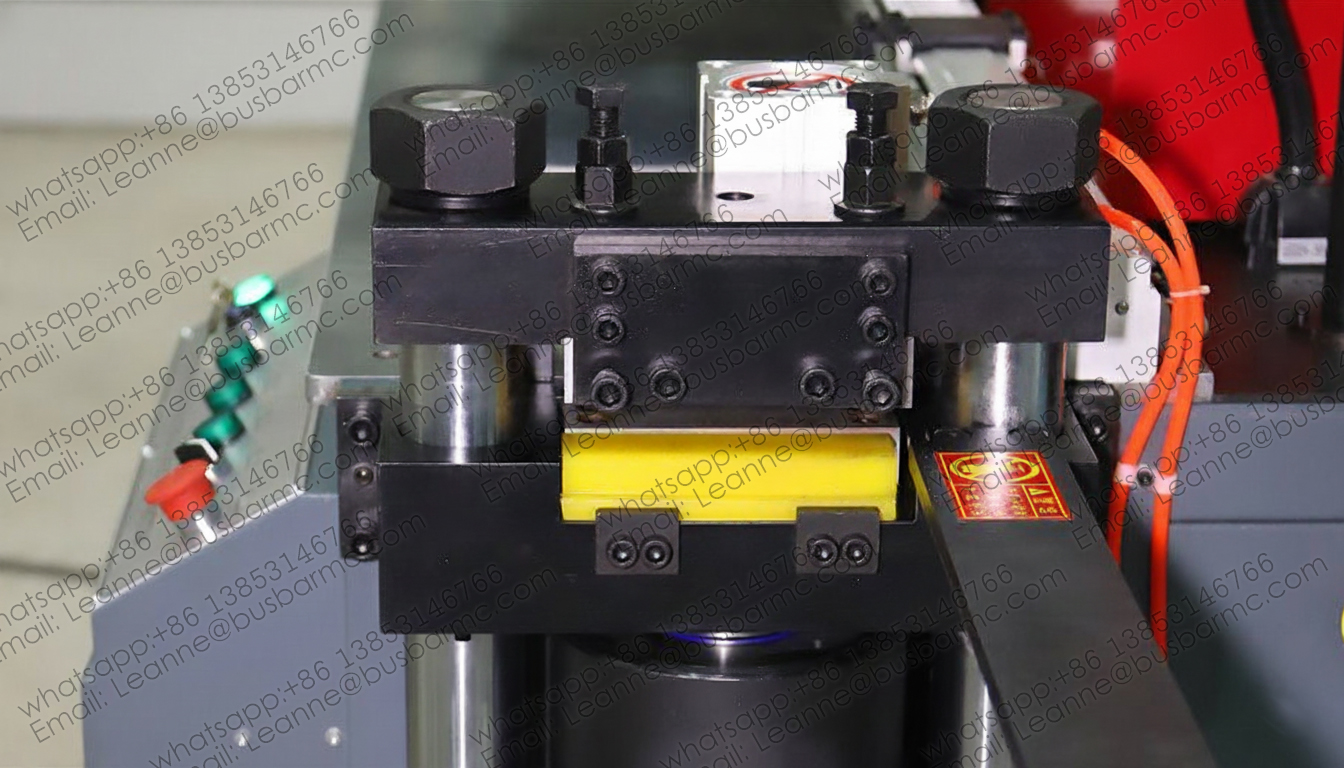

1. Shearing/Cutting Station (Burr-free Finish):

2. Punching Station (Precision Holes):

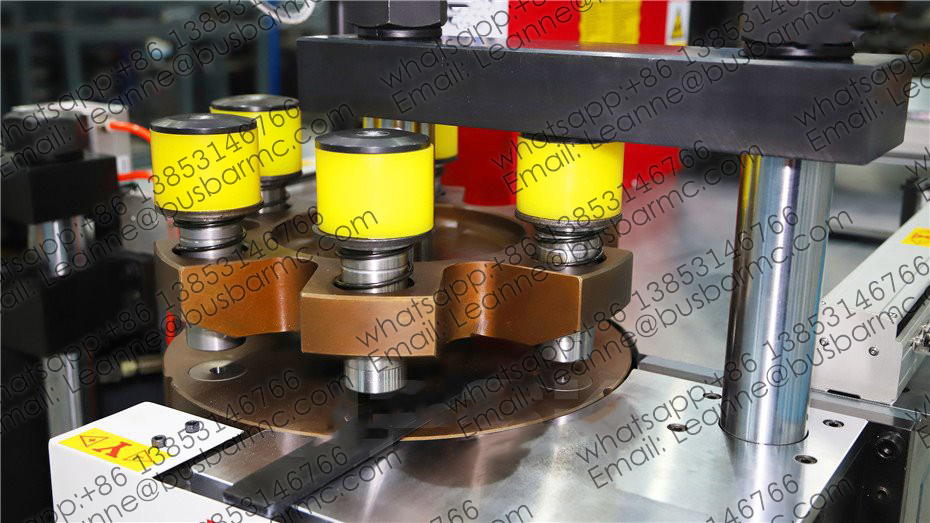

3. Bending Station (Vertical & Horizontal):

Technical Parameters (Model: 303U-3-C):

Function | Item | 303U-3-C |

Punching Unit | Max. Punching Force (KN) | 300 |

Punching Diameter Range (MM) | Ø4.3 - Ø25 | |

Max. Thickness (MM) | 12 | |

Max. Width (MM) | 160 | |

Shearing/Cutting Unit | Max. Shearing Thickness (MM) | 12 |

Max. Shearing Width (MM) | 160 | |

Vertical Bending | Max. Bending Force (KN) | 300 |

Max. Thickness (MM) | 12 | |

Max. Width (MM) | 160 | |

Horizontal Bending | Max. Width (MM) | 100 |

Max. Angle (Degree) | 90° | |

General Specs | Outer Dimensions (MM) | 1800 * 1400 * 1480 |

Motor Power | KW | 3 * 4kw |

Weight | KG | 1420kg |

CNC Precision | Bending Precision | ±1° |

Repeat Bending Precision | ±0.3° |

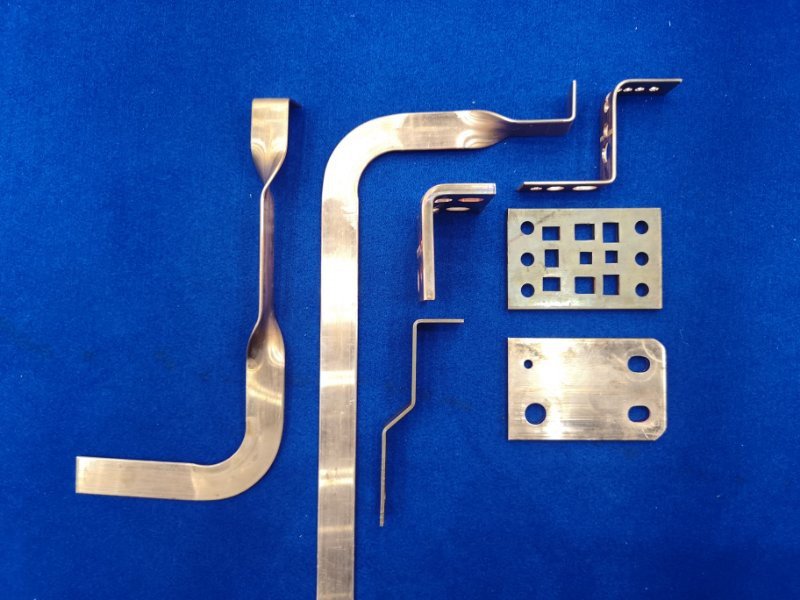

Processing Samples (Copper & Aluminium):

Our Manufacturing Factory:

Hot Tags (Australia): Premium Copper/Aluminium Busbar Processing Machine,

Keywords: hydraulic busbar machine Australia, 3-in-1 busbar processor, switchboard manufacturing equipment, copper bar bender, aluminium busbar puncher, switchgear assembly tools, busbar cutting machine, CNC busbar bending machine, electrical panel builder tools, copper busbar fabrication, power distribution machinery, busbar machine suppliers, heavy duty busbar bender.

Watch the LT Busbar Machine in Action:

FAQ – Premium 3-in-1 Copper/Aluminium Busbar Machine

1. What specific functions does this 3-in-1 machine offer?

This unit combines three essential functions for switchboard builders: punching, shearing (cutting), and bending. Each station operates independently for maximum efficiency.

2. Which materials is this machine designed to process?

It is engineered to process both Copper and Aluminium busbars (Cu/Al), adhering to the high standards required for Australian power distribution projects.

3. What is the maximum punching force available?

The punching unit delivers a robust force of 300KN, ensuring clean holes in thick bars.

4. What range of hole diameters can be punched?

The standard punching range is from Ø4.3mm to Ø25mm, covering most bolt sizes used in electrical panels.

5. What is the maximum busbar size for the punching station?

It accommodates busbars up to 12mm in thickness and 160mm in width.

6. What is the capacity of the shearing/cutting unit?

The shearing station can cleanly cut busbars up to 12mm thick and 160mm wide without waste.

7. How powerful is the bending unit?

The vertical bending station provides a maximum bending force of 300KN.

8. What are the dimensional limits for bending?

Vertical bending: max 12mm x 160mm. Horizontal bending: max width 100mm with a maximum angle of 90°.

9. How precise is the bending angle?

The machine offers high precision suitable for quality switchgear, with bending accuracy of ±1° and repeat accuracy of ±0.3°.

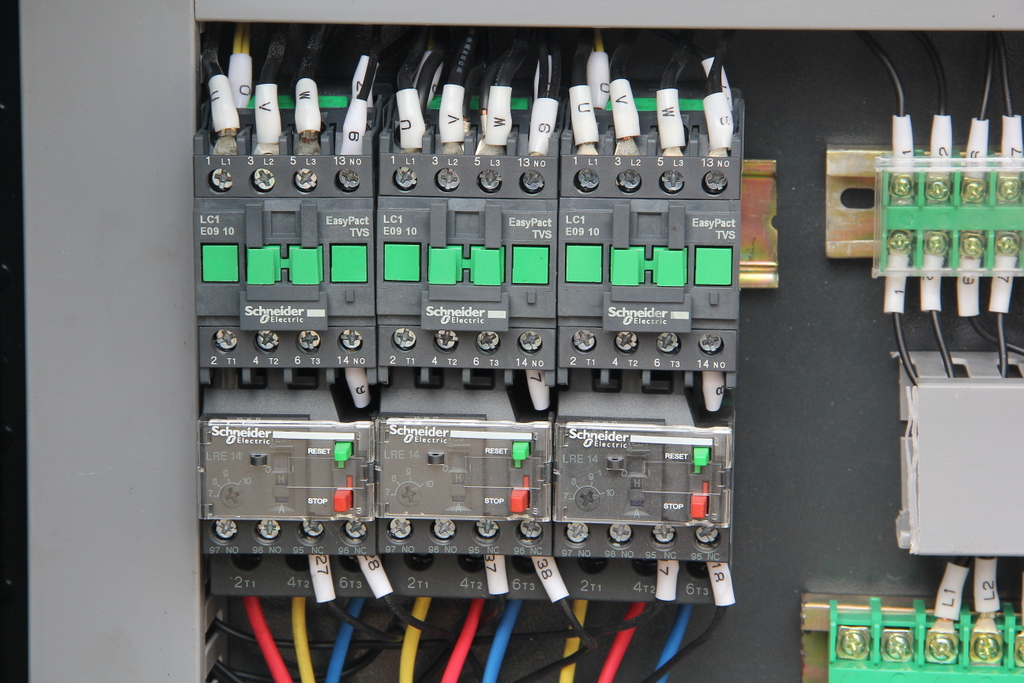

10. What are the power requirements?

The machine utilises 3 × 4kW hydraulic motors, allowing simultaneous operation of different units if required.

11. What is the machine's footprint and weight?

Dimensions: 1800mm × 1400mm × 1480mm. Weight: approx. 1420kg. It is a solid, stable unit for industrial workshops.

12. Can the workstations be adjusted?

Yes, each unit (punching, shearing, bending) is fully adjustable to minimise setup time between batches.

13. Which Australian industries use this machine?

It is widely used by Switchboard Manufacturers, Electrical Panel Builders, Switchgear Assemblers, Mining Electrical Contractors, and Power Distribution Fabricators.

14. Is the tooling interchangeable?

Yes, punching dies can be quickly changed to suit various hole sizes (e.g., M8, M10, M12 clearance holes).

15. How can I get a quote for delivery to Australia?

Please contact our sales team for the latest pricing, shipping rates to major Australian ports, and technical specifications.

Australian Industry Tags & Keywords:

3-in-1 busbar processing machine Australia, copper and aluminium busbar bender, hydraulic busbar punching shearing bending machine, multifunction switchboard fabrication equipment, industrial busbar machine, busbar punching cutting bending unit, combined busbar machine, copper busbar fabrication machine, aluminium busbar processing equipment, electrical switchgear tools, heavy-duty busbar fabrication system, high-precision busbar bending machine, copper bar punching and cutting machine, manual and hydraulic busbar bending equipment, switchgear busbar fabrication machine, power distribution busbar processing machinery, electrical panel busbar fabrication equipment, three-station busbar machine, integrated hydraulic busbar machine, workshop busbar processing equipment, copper bar forming and bending system, busbar workshop production machine, compact multifunction busbar processor, copper strip processing machine, switchboard builders tools, electrical switchboard manufacturer equipment, sparky tools Australia.