<input type="hidden" id="productID" name="productID" value="196017412"/>

503U-3-C Heavy Duty CNC Busbar Processing Machine (16mm x 200mm)

1. Main Picture:

This robust 503U-3-C Hydraulic Busbar Processing Machine (Capacity: 16mm x 200mm) integrates three heavy-duty workstations: punching, shearing, and bending. Each unit is independently adjustable, significantly shortening processing times and boosting production efficiency for high-volume switchboard manufacturers.

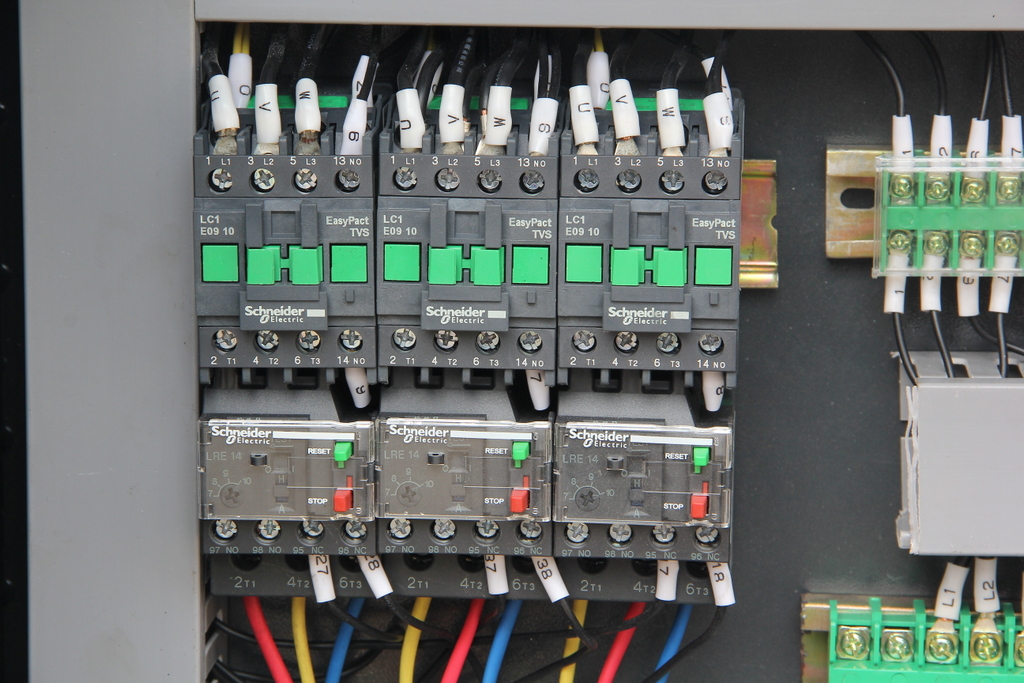

The bending unit is equipped with a premium imported PLC control system (Siemens/Panasonic optional), ensuring high stability and superior bending precision. It is specifically engineered to process large Copper and Aluminium busbars of various specifications. Through its versatile operation units, it can quickly perform a wide range of fabrication tasks including shearing, punching (circular and oblong holes), flat bending, vertical bending, and knurling. By changing molds, this CNC machine can also handle specialized processes such as flat pressing, embossing, cable connector processing, copper bar twisting, and flat crushing.

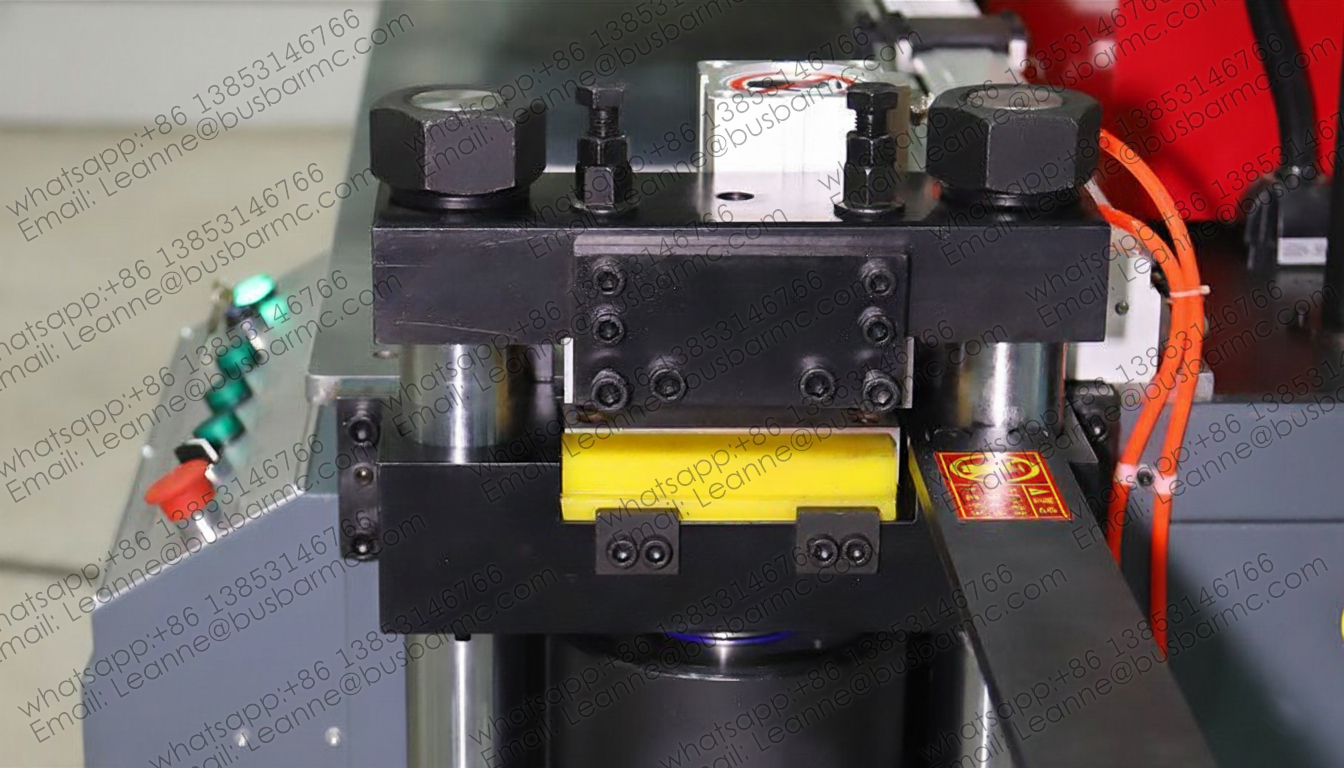

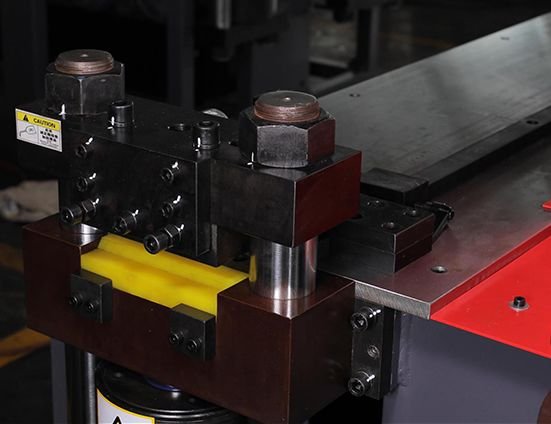

2. Three Working Units Detail:

1) Punching Unit (Precise & Clean):

2) Shearing Unit (Burr-free Cutting):

3) Bending Unit (PLC Controlled):

For lighter duty requirements, you may also consider our Premium Copper/Aluminium Busbar Processing Machine which is ideal for smaller workshops.

3. Packing and Shipment:

1) Waterproofing: The machine is wrapped in a protective plastic film to prevent moisture and corrosion.

2) Safety Crating: The unit is securely packed in a fumigated wooden case suitable for long-distance export.

4. Customer Service & Support:

We provide a 24-hour dedicated hotline for all our clients post-purchase.

Our technical team is ready to solve any operational issues via video conference. Quality is our promise, and we aim to be your trusted CNC Busbar Machine Partner in China.

E-mail: Leanne@busbarmc.com

Whatsapp: +8613853146766

Skype: Leanne.Li88

www.busbarmc.com

Hot Tags (Australia): 503U-3-C CNC busbar processing machine 16mm 200mm, CNC busbar machine Australia, 3-in-1 busbar machine, hydraulic busbar bending machine, aluminium busbar punching machine, copper busbar cutter, heavy duty busbar bender, CNC punching machine, switchboard manufacturing equipment, busbar machine suppliers, copper busbar machine price, machine bending tools, China factory direct.

Watch the 503U-3-C in Action (Video):

FAQ – 503U-3-C Heavy Duty CNC Busbar Machine

1. What is the primary capacity of the 503U-3-C model?

The 503U-3-C is a heavy-duty machine integrating punching, shearing, and bending units. It is specifically designed to process Copper and Aluminium busbars up to 16mm in thickness and 200mm in width.

2. Does the bending unit feature CNC control?

Yes, the bending station is equipped with an imported PLC control system (e.g., Siemens). This ensures precise bending angles and high repeatability, essential for switchgear assembly.

3. What materials can be processed?

It is suitable for both Copper (Cu) and Aluminium (Al) busbars used in power distribution transformers and electrical panels.

4. What punching shapes are supported?

Standard dies include circular and oblong holes. We also offer custom molds for embossing, knurling, or special connector holes upon request.

5. Can I perform special functions like embossing or twisting?

Yes. By simply changing the tooling dies, the machine can perform embossing, flat pressing, cable connector processing, and even twisting of copper bars.

6. How does the 3-unit design improve efficiency?

The punching, shearing, and bending units can be operated and adjusted independently. This allows for multitasking and significantly reduces production lead times.

7. What industries in Australia use this machine?

It is widely used by Switchboard Manufacturers, Electrical Panel Builders, Switchgear Assemblers, Mining Electrical Contractors, and Transformer Factories.

8. Is the packaging suitable for international shipping?

Absolutely. The machine is wrapped in protective plastic to prevent moisture damage and then secured in a sturdy wooden crate for safe sea freight.

9. How do I get technical support after purchase?

We offer 24/7 online support. Our engineers can guide your team via video call to resolve any operational queries or maintenance needs.

10. Can the molds be changed easily?

Yes, the quick-change die system allows operators to switch between punching sizes or bending tools rapidly.

11. What is the maximum processing size?

Max Thickness: 16mm. Max Width: 200mm.

Australian Market Keywords & Tags:

503U-3-C heavy duty busbar machine, CNC hydraulic busbar processor, copper aluminium busbar punching shearing bending machine, automated busbar fabrication equipment, industrial switchboard machinery, busbar punching cutting bending machine, multifunction busbar machine, copper busbar processing equipment, aluminium busbar processing machine, hydraulic busbar bending unit, high-precision busbar punching machine, heavy-duty copper bar cutting machine, electrical panel busbar fabrication machine, switchgear busbar processing equipment, workshop busbar fabrication machine, PLC-controlled busbar bending system, copper bar forming and bending machine, oblong and round hole punching busbar machine, flat and vertical busbar bending equipment, three-station hydraulic busbar machine, busbar punching press machine, hydraulic copper bar fabrication system, power distribution busbar processing machine, compact hydraulic busbar workstation, electrical industry busbar fabrication machine, switchboard builders tools Australia, sparky tools, high amperage busbar bender.