<input type="hidden" id="productID" name="productID" value="75467010"/>

Product Description: 303U-3-C Manual Hydraulic Busbar Machine

Model: 303U-3-C

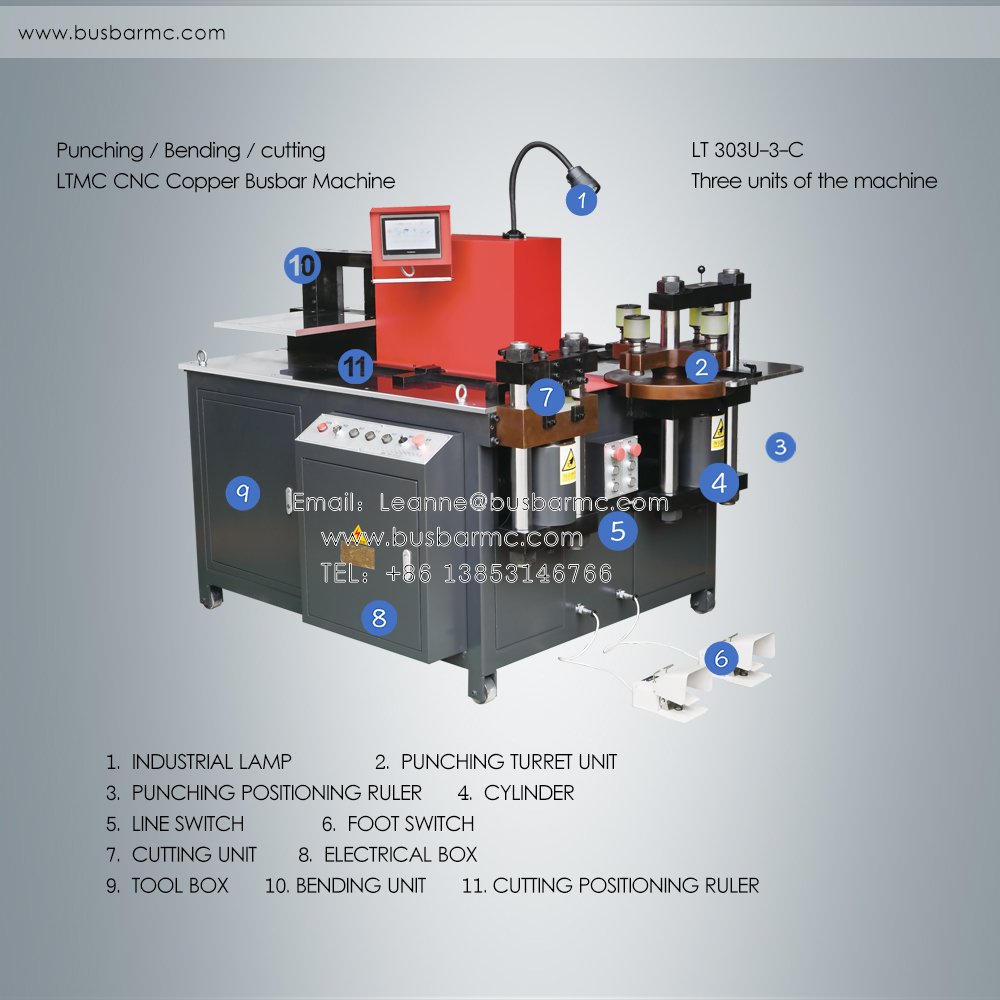

This versatile series of 3-in-1 Busbar Processing Machines integrates three essential workstations: punching, shearing/cutting, and bending. The three units can be operated simultaneously or sequentially, allowing for maximum flexibility in your workshop. The working stroke of each unit is easily adjustable, which significantly shortens processing time and boosts production efficiency for switchboard builders. Its primary function is the fabrication of Copper and Aluminium busbars.

Equipped with independent hydraulic units for punching, shearing, and bending, this machine offers precise control via manual buttons or a foot switch. You can punch, cut, and bend busbars separately, making it an ideal production asset for the high and low voltage electrical industry in Australia.

Designed with reference to advanced international engineering standards and tailored for practical site conditions, this busbar machine improves workflow efficiency while ensuring operational safety. It is perfectly suited for construction sites, large-scale electric control box assembly, and power transmission and distribution projects.

Product Details & Components:

1. Industrial Work Lamp 2. Turret Punching Unit 3. Punching Positioning Ruler 4. Hydraulic Cylinder 5. Safety Line Switch 6. Foot Switch Pedal 7. Shearing/Cutting Unit 8. Electrical Control Box 9. Tool Box 10. Bending Unit 11. Cutting Positioning Ruler

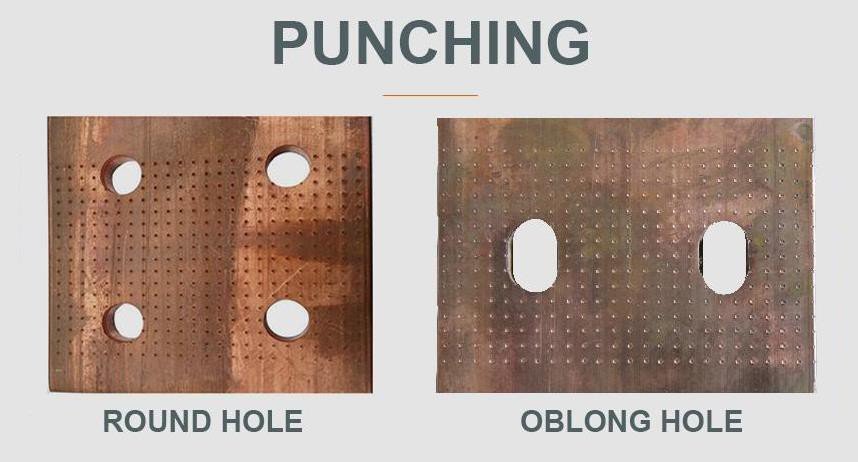

Processing Samples (Copper & Aluminium):

Capable of punching clean round holes and oblong holes for bolt connections.

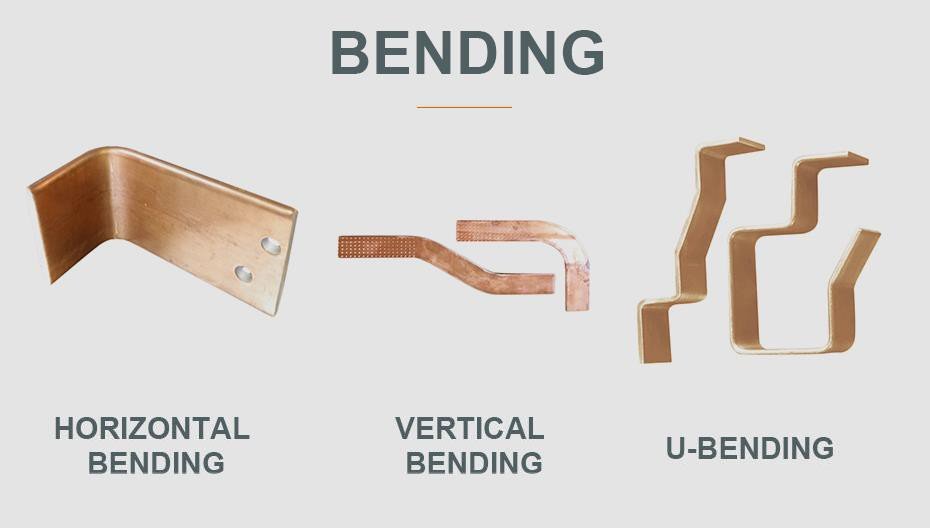

Ideally suited for horizontal bending, vertical bending, and U-bending.

With optional tooling, the machine also supports embossing, twisting, and cable connector processing functions.

Our Factory:

As a Leading Busbar Machine Manufacturer, we ensure every unit meets strict quality standards before shipping to Australia.

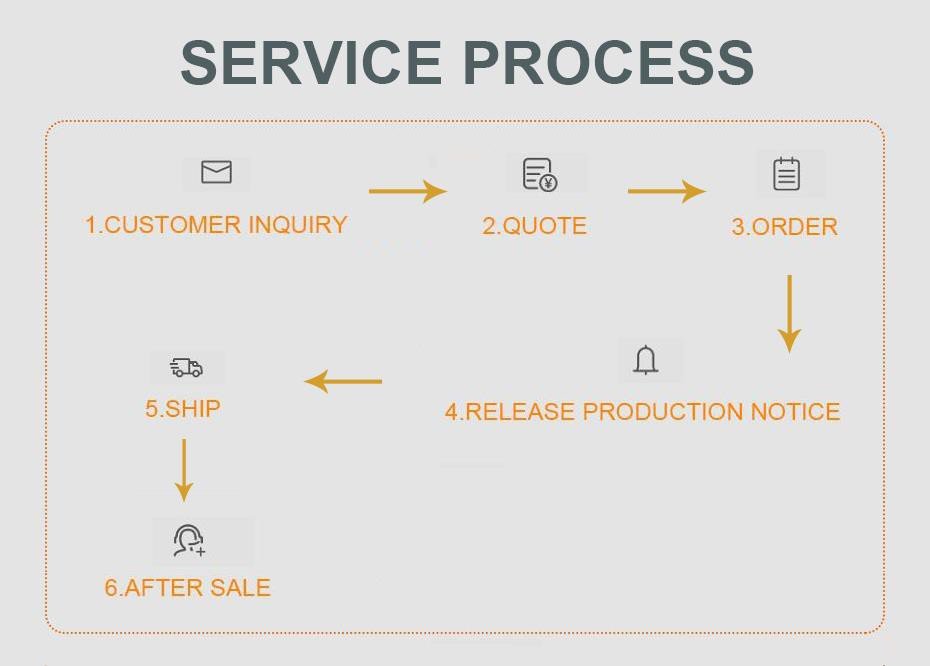

Our Service Process:

Our dedicated after-sales service engineers conduct regular follow-ups to listen to your feedback and ensure your machine is performing optimally.

Package & Delivery:

We ensure safe transit with waterproof plastic film wrapping inside and sturdy export-grade wooden cases outside.

Our Certifications:

Our ISO9001 quality assurance system is the foundation of our enterprise's growth. ISO9001 represents our commitment to international standards, ensuring you receive a reliable and high-quality product.

Technical Parameters:

Item | Model | |

303U-3 | 303U-3-C | |

Nominal force (kn) | 300 | 300 |

Punching dia. range (mm) | ф4.3~ф25 | ф4.3~ф25 |

Max.thickness (mm) | 12 | 12 |

Max.width (mm) | 150 | 150 |

Max.shearing thickness (mm) | 12 | 12 |

Max.shearing width (mm) | 150 | 150 |

Max.horizontal bending width (mm) | 150 | 150 |

Max.horizontal bending thickness (mm) | 12 | 12 |

Max.vertical bending size (mm) | 10×100 | 10×100 |

Power (kw) | 1×4KW | 3×4KW |

Table size (mm) | 1650×1050 | 1650×1050 |

Outside dimension (mm) | 1720×1220×1220 | 1720×1220×1220 |

Container size (mm) | 1800×1300×1430 | 1800×1300×1430 |

Total weight (kg) | 1220KG | 1320KG |

If you require higher processing capacity (up to 16mm x 200mm) or automatic control, please consider our Heavy Duty CNC Busbar Machine.

Main Features for Australian Users:

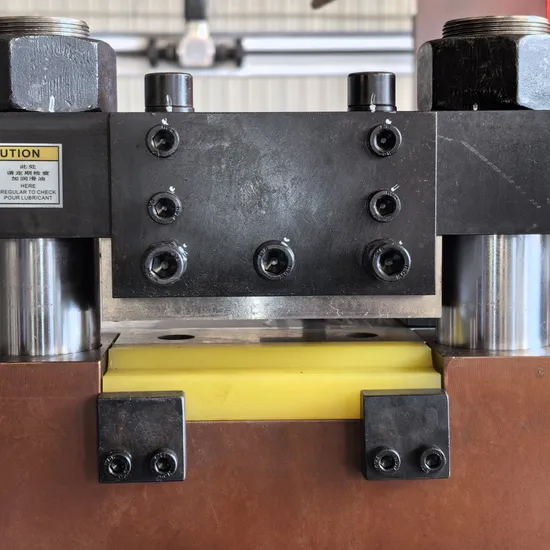

1. Shearing Unit: Uses a vertical processing mode with flat blade cutting, ensuring a burr-free, waste-free, and smooth interface.

2. Punching Unit: Equipped with a six-mode turret turnplate (tooth shape) for better visibility. No need to frequently change dies, making operation simple and efficient.

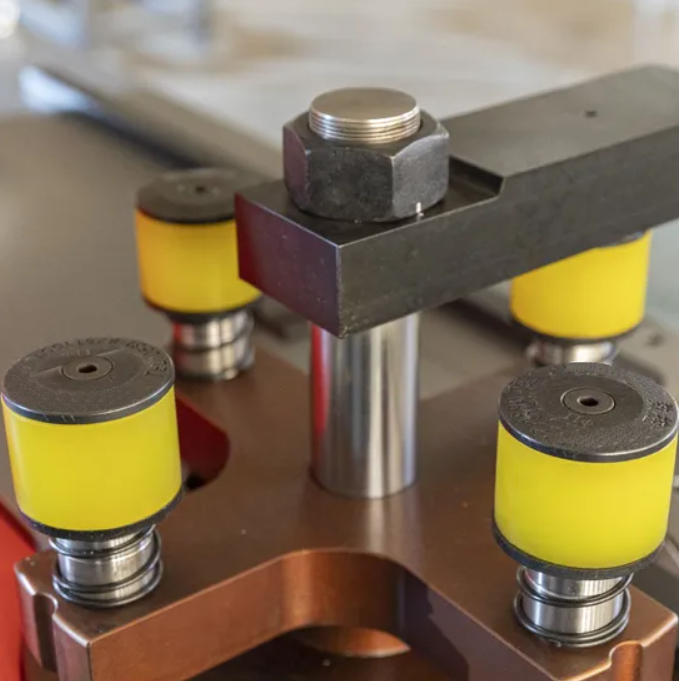

3. Bending Unit: Features a horizontal bending station. By simply changing molds, you can switch between flat bending and vertical bending easily.

4. Versatility: Additional functions like embossing, flattening, twisting, and cable end crimping can be achieved with specific molds.

5. Mobility: Mounted on four heavy-duty casters, allowing easy movement around your workshop or construction site.

6. Customisation: We provide different molds and tools tailored to user requirements for special shape processing.

Hot Tags (Australia): 303U-3-C Manual Hydraulic Busbar Machine, 3-in-1 busbar machine Australia, copper busbar bender, aluminium busbar processing equipment, manual hydraulic busbar puncher, switchboard manufacturing tools, electrical panel fabrication machine, mobile busbar machine, hydraulic busbar cutter, busbar machine suppliers.

Watch the 303U-3-C in Action (Video):

FAQ – 303U-3-C Manual Hydraulic Busbar Machine

1. What is the primary use of the 303U-3-C machine?

This 3-in-1 manual hydraulic machine is designed for punching, shearing (cutting), and bending copper and aluminium busbars. It is widely used in Australia's high and low voltage electrical industry for switchboard assembly.

2. Can all three stations operate at once?

Yes, the punching, cutting, and bending units have independent hydraulic circuits, allowing them to work simultaneously or sequentially to boost workshop efficiency.

3. How is the machine controlled?

It is operated via manual buttons or a convenient foot switch, giving the operator hands-free control for precise positioning of the busbar.

4. Why is the turret punching unit advantageous?

The six-mode turnplate design means you don't have to change dies frequently. It also provides a clear view of the workpiece for accurate alignment.

5. What are the key technical specifications?

Nominal Force: 300 kN; Punching Range: Ø4.3–Ø25 mm; Max Thickness: 12 mm; Max Width: 150 mm; Total Power: 3×4 kW; Weight: 1320 kg.

6. Is this machine suitable for on-site work?

Yes, its robust design and mobility (via casters) make it excellent for large-scale construction sites and power distribution projects.

7. How is the machine packaged for export to Australia?

We wrap the machine in waterproof plastic film and secure it in a fumigated wooden crate to ensure it arrives in perfect condition.

8. What safety and quality standards does it meet?

The machine is manufactured under strict ISO9001 quality management standards, ensuring reliability and safety for operators.

9. Can it handle custom bending shapes?

Yes, by installing different molds, you can perform vertical bending, U-bending, embossing, twisting, and crimping tailored to your project needs.

10. Do you provide after-sales support?

Absolutely. Our engineers provide regular follow-ups and are available for video support to address any operational questions.

Local Industry Keywords & Tags:

303U-3-C busbar machine, 3 in 1 hydraulic busbar machine, manual busbar processing machine, copper busbar bending machine, aluminium busbar processing equipment, CNC busbar punch shear bend machine, high voltage busbar machine, low voltage busbar machine, portable busbar machine, industrial electrical busbar machine, customizable busbar processing machine, busbar fabrication machine, multi-function busbar machine, compact busbar machine, hydraulic busbar bending press, switchboard builder tools, sparky equipment, electrical panel manufacturing, power distribution tools, busbar bender Australia.