<input type="hidden" id="productID" name="productID" value="75271545"/>

Product Description: 303U-3 Simultaneous Hydraulic Busbar Machine

The LT-303U-3 Busbar Processing Machine is a high-performance industrial unit designed for the Australian switchboard manufacturing sector. Unlike standard single-motor machines, this 3-in-1 Busbar Machine features three independent motors and hydraulic pumps. This allows three operators to perform punching, shearing, and bending simultaneously without power loss, maximizing your workshop's productivity.

It is specifically engineered to process Copper and Aluminium busbars up to 12mm in thickness and 160mm in width.

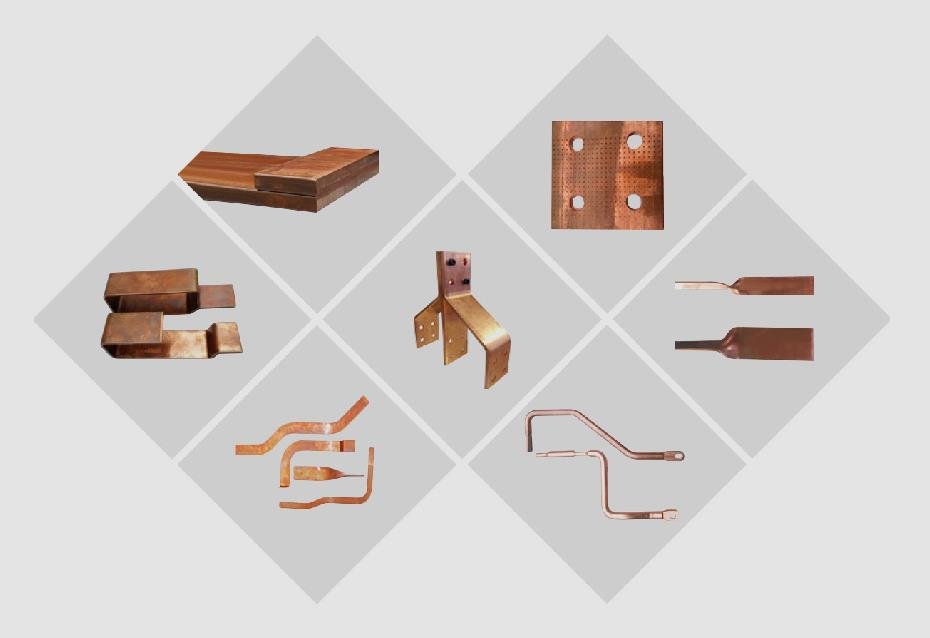

Processing Capabilities & Samples:

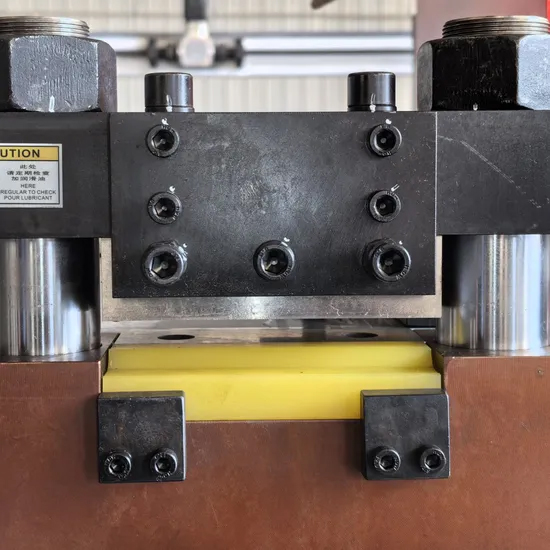

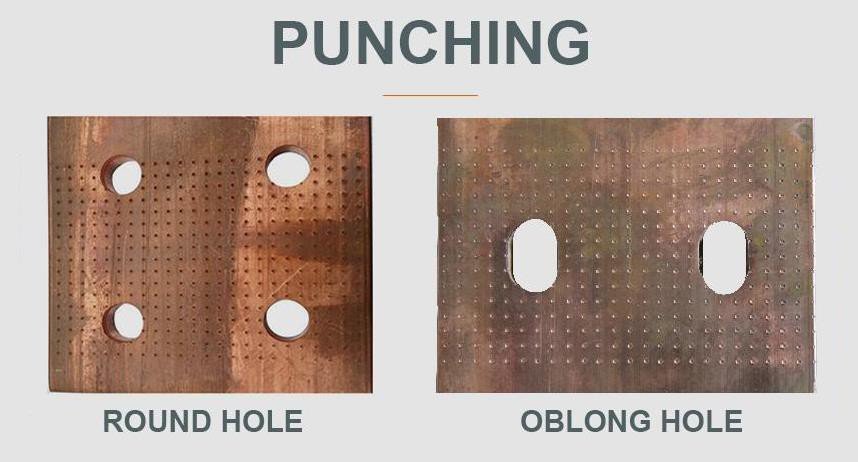

1. Punching Station:

Capable of punching precise round holes, oblong holes, and square holes for standard switchgear bolts.

2. Shearing/Cutting Station:

Uses a sharp shearing blade to ensure the cutting surface is flat, smooth, and burr-free, reducing waste.

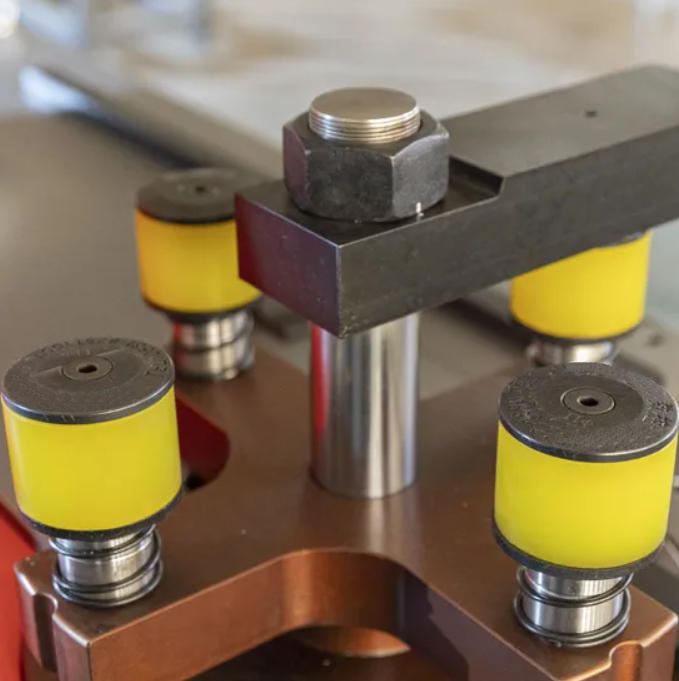

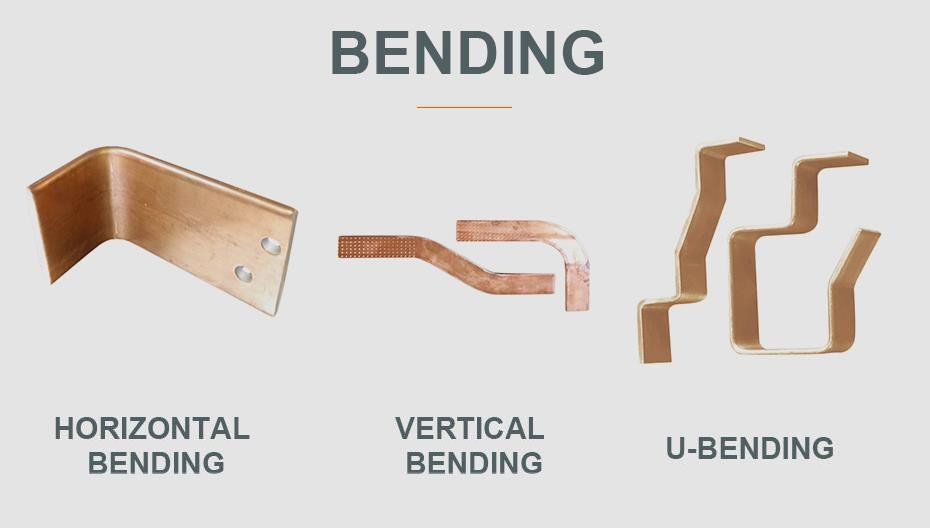

3. Bending Station:

Ideally suited for vertical bending, flat (horizontal) bending, and U-bending for complex switchboard layouts.

Versatile Functions (With Optional Moulds):

By changing the tooling, this machine can also perform embossing, twisting, cable connector crimping, and more.

If your workshop has lower volume requirements, you might consider our manual single-pump model, the 303U-3-C Manual Hydraulic Busbar Machine.

Our Service & Global Reach:

As a trusted Busbar Machine Manufacturer, we take full responsibility for your after-sales experience. We have successfully served clients in over 100 countries, including Australia.

If you encounter any operational issues, feel free to contact us. We provide support for machine setup, troubleshooting, and maintenance.

Contact Us:

WhatsApp: +8613853146766

Skype: Leanne.Li88

Official Website: http://www.busbarmc.com/

E-mail: Leanne@busbarmc.com

Technical Parameters:

| Items | Model |

| 303U-3 | |

| Nominal force (kn) | 300 |

| Punching dia. range (mm) | ф4.3~ф25 |

| Max. thickness (mm) | 12 |

| Max. width (mm) | 160 |

| Max. shearing thickness (mm) | 12 |

| Max. shearing width (mm) | 160 |

| Max. horizontal bending width (mm) | 160 |

| Max. Horizontal bending thickness (mm) | 12 |

| Max. vertical bending size (mm) | 10×100 |

| Power (kw) | 3×4KW (3 Motors) |

| Bending precision (degree) | ±1° |

| Repeat bending precision (degree) | ±0.5° |

| First table size (mm) | 1650×1050 |

| Second table size (mm) | ----- |

| Outside dimension (mm) | 1720×1220×1240 |

| Container size (mm) | 1800×1300×1450 |

| Total weight (kg) | 1320KG |

Hot Tags (Australia): 303U-3 Simultaneous Hydraulic Busbar Machine,

Keywords: 3-in-1 busbar machine Australia, hydraulic busbar bender, copper busbar punching machine, aluminium busbar cutter, switchboard manufacturing equipment, simultaneous busbar processing, CNC busbar machine, electrical panel builder tools, copper bar bending machine, busbar fabrication machinery, heavy duty busbar machine, switchgear assembly tools.

Watch the LT-303U-3 in Action:

FAQ – 303U-3 Hydraulic Busbar Processing Machine

1. What makes the 303U-3 different from other models?

The key advantage of the 303U-3 is its three independent motors and pumps (3×4KW). This allows three operators to work on punching, shearing, and bending units simultaneously, drastically increasing production speed compared to single-motor units.

2. What is the maximum busbar size this machine can process?

It is designed for copper and aluminium busbars up to 12mm in thickness and 160mm in width.

3. What specific functions are integrated?

The machine combines punching (round/oblong/square holes), shearing (flat cutting), and bending (vertical/horizontal/U-shape) in one workstation.

4. Can I use this for Australian standard switchboards?

Absolutely. The machine is precise and robust, making it perfect for manufacturing switchboards compliant with Australian standards (AS/NZS 3000/61439).

5. How accurate is the bending unit?

The bending unit offers high precision with a tolerance of ±1° and a repeat bending accuracy of ±0.5°, ensuring consistent quality for mass production.

6. Is it easy to change functions or moulds?

Yes. The punching dies and bending moulds are designed for quick changes. You can switch from flat bending to vertical bending or embossing in minutes.

7. What power supply does it need?

The standard configuration is 3-phase power to support the 3×4KW motors. We can customize the voltage to match your local Australian power supply (e.g., 415V).

8. Is the machine mobile?

Yes, despite its heavy-duty capacity (1320kg), it is equipped with sturdy casters, allowing you to reposition it within your workshop.

9. What kind of after-sales support do you offer?

We provide comprehensive support via WhatsApp, Skype, and Email. We can guide you through installation, operation, and maintenance remotely.

Local Industry Tags:

copper busbar bending machine, busbar cutting machine, busbar punching machine, hydraulic busbar machine, 3-pump busbar machine, electrical busbar processing machine, busbar fabrication machine, flat bending busbar machine, vertical bending busbar machine, U-bending busbar machine, cable end crimping machine, embossing busbar machine, industrial busbar machine, high voltage busbar machine, low voltage busbar machine, busbar production equipment, copper aluminium busbar machine, busbar machinery suppliers, busbar machine factory, CNC bending punching cutting machine, busbar manufacturing machine, electrical distribution busbar machine, busbar processing tools, hydraulic bending punching machine, custom busbar machine, switchboard assembly tools Australia.