Product Overview & Specifications

Product Image

Product Introduction

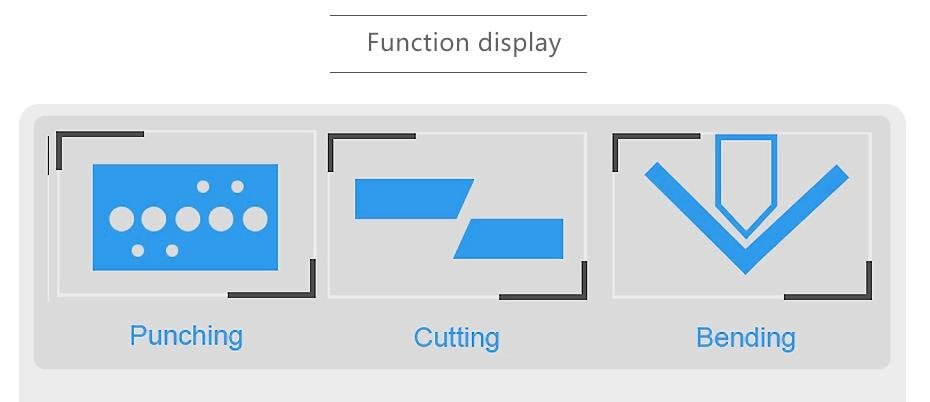

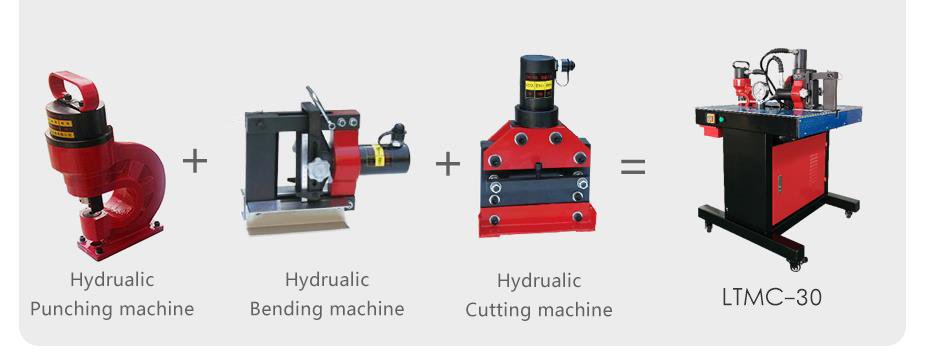

The LTMC-30A is a versatile powerhouse designed for the Australian electrical industry. It integrates three core processing units: punching, shearing (cutting), and bending. It is engineered specifically for processing copper and aluminium busbars across various specifications, making it an essential tool for efficient switchboard manufacturing and site fit-outs.

Processing Capabilities

PUNCH / SHEAR / BEND

The max. processing width is 150mm.

The max. processing thickness is 10mm.

Industry Applications

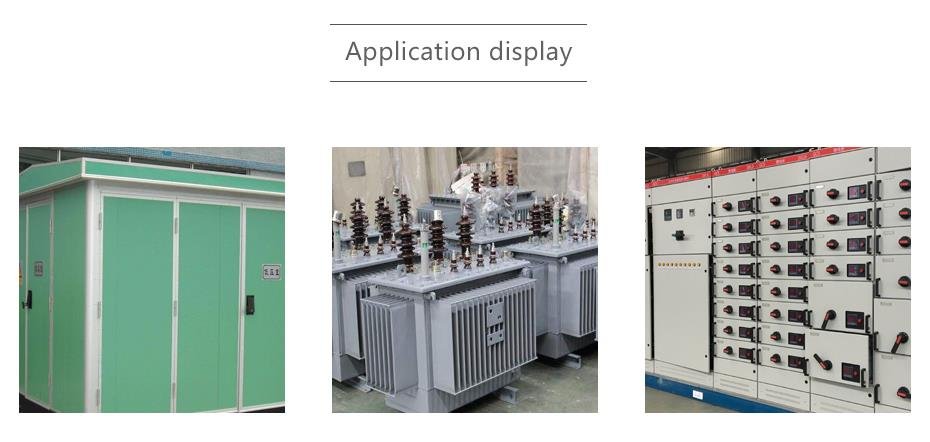

The machine operates on a single-phase 220V ordinary power supply, making it highly adaptable for any location. It is perfect for on-site construction of large workshops, transmission and distribution work, and electrical manufacturing plants producing power distribution cabinets and switchboards. For those looking for a wider range of site-ready equipment, explore our portable multi-function busbar units suitable for various project scales.

This unit is widely used in high and low voltage switchgear, substations, busways, electrical switches, communication equipment, and chassis manufacturing. It is the most suitable solution for making large electric control boxes and for use at transmission and distribution construction sites across Australia.

Compact Single Processing Unit

Why Choose Us?

Manufacturing Excellence

As a premier supplier of CNC busbar machinery, we have professional engineers to serve you from the beginning to the end.

We guarantee superior product quality and reliable service for all our Australian clients.

Our Certifications

Global Business Partners

Trusted by industry leaders such as ABB, Siemens, Schneider, and EDK.

Global Reach

Our products are exported to more than 100 countries worldwide.

Including Australia, New Zealand, the United States, Britain, Germany, Russia, Canada, and many more. If you require higher capacity, check out our advanced hydraulic copper & aluminium processor for heavy-duty industrial fabrication.

Due to superior product performance, powerful functions, stable quality, and timely after-sales service, we have won unanimous praise from customers and maintained long-term friendly cooperation.

Technical Parameters

| Item | Model |

| LTMC-30 | |

| Rated oil pressure (kn) | 630 |

| Max. processing width (mm) | 150 |

| Max. processing thickness (mm) | 10 |

| External Dimensions (mm) | 700×700×1100 |

| Diameter of standard dies (mm) | ¢10.5、¢13.8、¢17、¢20.5 |

| Input voltage | 220V/50HZ |

| Container size (mm) | 990×760×1320 |

| Machine weight (kg) | 165 |

Hot Tags (Australia): LTMC-30 portable 3-in-1 busbar machine, copper busbar processor Australia, switchboard fit-out tools, hydraulic busbar bender,

Hot Tags: portable busbar punch shear bend, hydraulic busbar cutter, aluminium busbar bender, mobile electrical workshop tool, switchgear fabrication equipment, copper bar bending machine, busbar punching die, onsite busbar machine, electrical contractor tools, 3-in-1 busbar processor, busbar machine supplier Australia, busbar bending tool Melbourne, busbar cutting tool Sydney.

LTMC-30 Portable Busbar Machine FAQ

Q: What is the LTMC-30 busbar machine mainly used for in Australia?

A: The LTMC-30 integrates punching, shearing (cutting), and bending functions. It is primarily used for processing copper and aluminium busbars for switchboards, power distribution cabinets, and onsite electrical fit-outs.

Q: What are the maximum processing specifications?

A: The LTMC-30 can handle busbars up to 150mm wide and 10mm thick, catering to most standard switchgear requirements.

Q: Is this machine suitable for onsite work?

A: Absolutely. It uses a single-phase 220V/50HZ power supply (compatible with standard mains power) and features a compact design (700×700×1100mm, 165kg), making it ideal for mobile workshops and construction sites.

Q: What industries benefit from this equipment?

A: It is widely used in high and low voltage switchgear manufacturing, substations, busway projects, shipbuilding, elevator manufacturing, and general electrical equipment production.

Q: Does it come with standard punching dies?

A: Yes, the machine includes standard die diameters of ¢10.5, ¢13.8, ¢17, and ¢20.5mm. Custom dies can often be arranged upon request.

Q: What support do you offer to Australian customers?

A: We provide comprehensive support from professional engineers, including operation guidance and reliable after-sales service to ensure your production runs smoothly.

Q: Who are your partners?

A: We supply major global players like ABB, Siemens, Schneider, and EDK, with machines operating in over 100 countries including Australia, New Zealand, USA, UK, and Germany.

Australian Industry Keywords & Related Terms:

portable busbar bender Australia, hydraulic busbar cutter NSW, copper busbar punching tool QLD, switchboard manufacturing equipment, electrical fit-out tools, mobile busbar workshop, aluminium busbar fabrication, 3-in-1 busbar processor, LTMC-30 specifications, busbar bending machine price Australia, copper bar shearing tool, onsite electrical equipment, switchgear tooling, busbar processing center, hydraulic hole puncher for copper, busbar bending dies, electrical cabinet fabrication, busbar machine for sale Melbourne, busbar machine for sale Sydney, busbar machine for sale Brisbane, busbar machine for sale Perth, power distribution tools, electrical contractor machinery, compact busbar machine, manual vs hydraulic busbar bender, precision busbar cutting, busbar bending radius calculator, switchboard builders association, electrical trade tools, heavy duty busbar machine, CNC busbar machine alternative, portable hydraulic punch, copper busbar suppliers Australia, aluminium busbar suppliers, electrical substation maintenance tools.