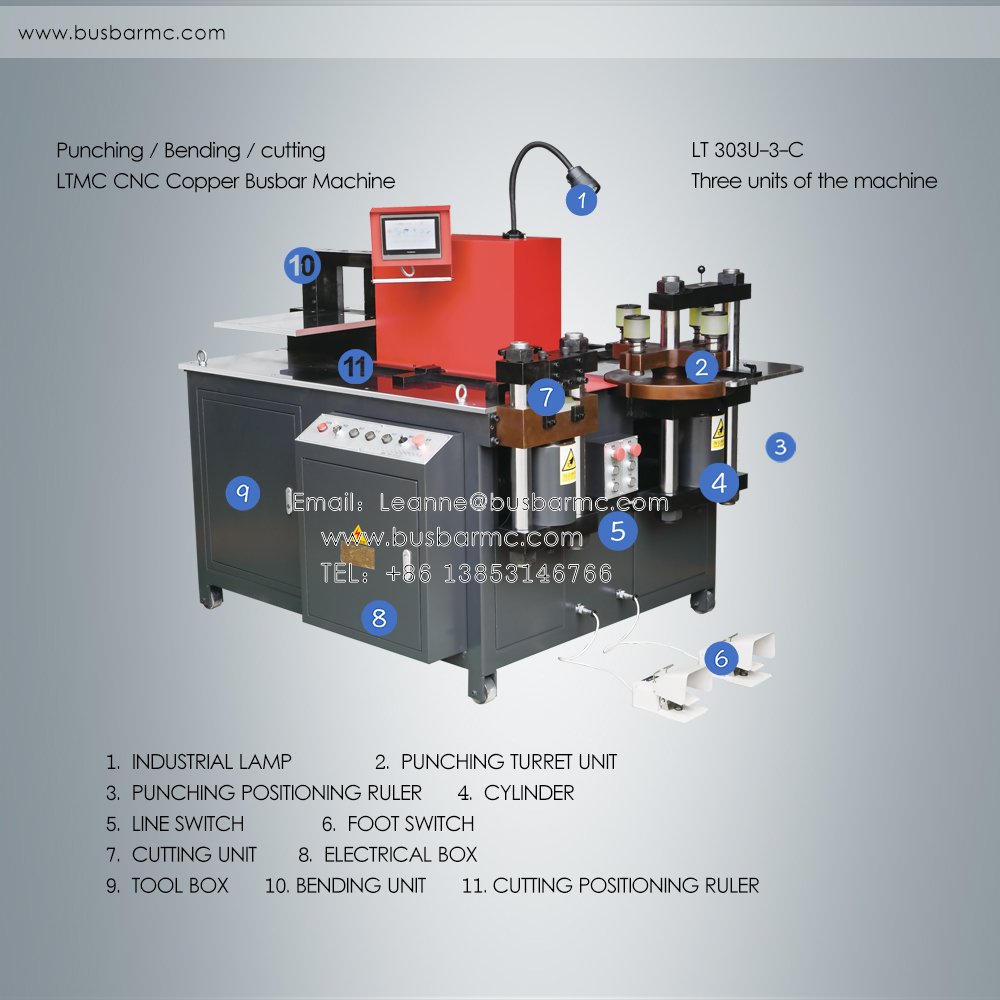

As a professional hydraulic busbar machinery supplier for the Australian market, we present the 303U-3-C Manual Hydraulic Busbar Machine.

This series of busbar processing machines features three independent processing units: punching, shearing (cutting), and bending. The three units can be operated simultaneously or sequentially. The working stroke of each processing unit can be easily adjusted, which significantly shortens processing time and improves production efficiency for switchboard builders. The main function is processing copper and aluminium busbars for electrical fit-outs.

Technical Parameters

Item | Model |

303U-3-C | |

Nominal force (kn) | 300 |

Punching dia. range (mm) | ф4.3~ф25 |

Max.thickness (mm) | 12 |

Max.width (mm) | 150 |

Max.shearing thickness (mm) | 12 |

Max.shearing width (mm) | 150 |

Max.horizontal bending width (mm) | 150 |

Max.horizontal bending thickness (mm) | 12 |

Max.vertical bending size (mm) | 10×100 |

Power (kw) | 1×4KW |

Table size (mm) | 1650×1050 |

Outside dimension (mm) | 1720×1220×1220 |

Container size (mm) | 1800×1300×1430 |

Total weight (kg) | 1220KG |

Key Features for Australian Workshops

1. The Shearing/Cutting Unit adopts a vertical processing mode, which is flexible and convenient to operate. It utilises a flat blade shearing method, ensuring the incision interface of the workpiece is flat, with no waste, no burrs, and no droop—meeting high-quality standards for switchboards.

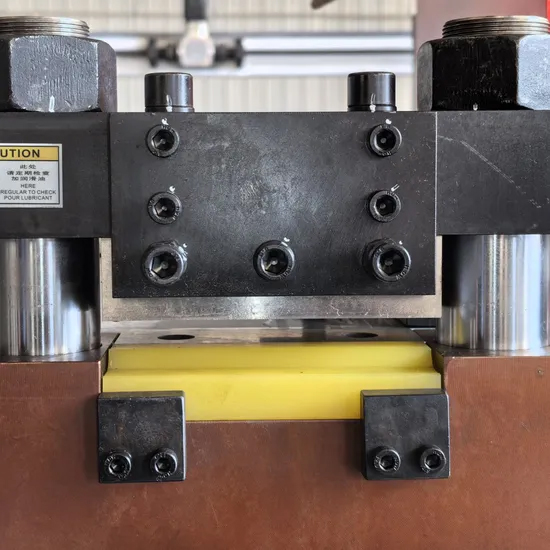

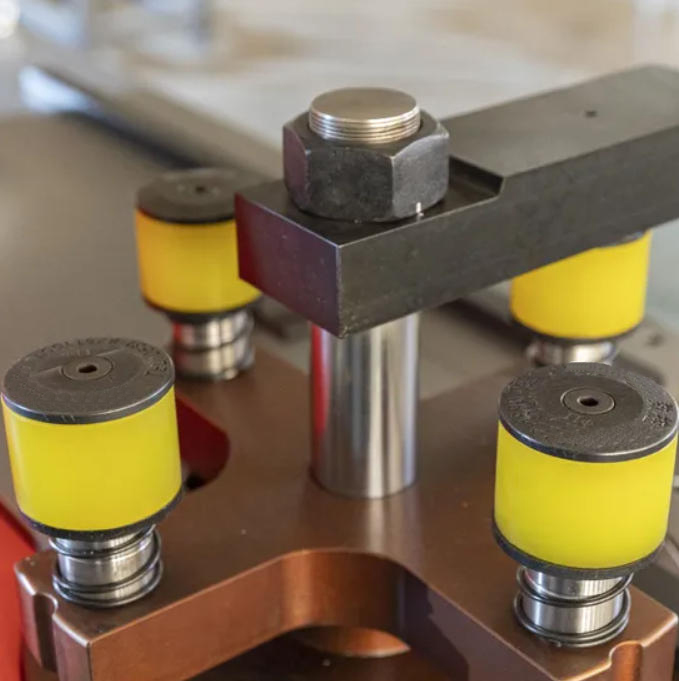

2. The Punching Unit uses a six-mode turnplate (turntable) in a tooth shape with excellent visibility. There is no need to change the dies frequently, making operation simple and efficient for electrical contractors.

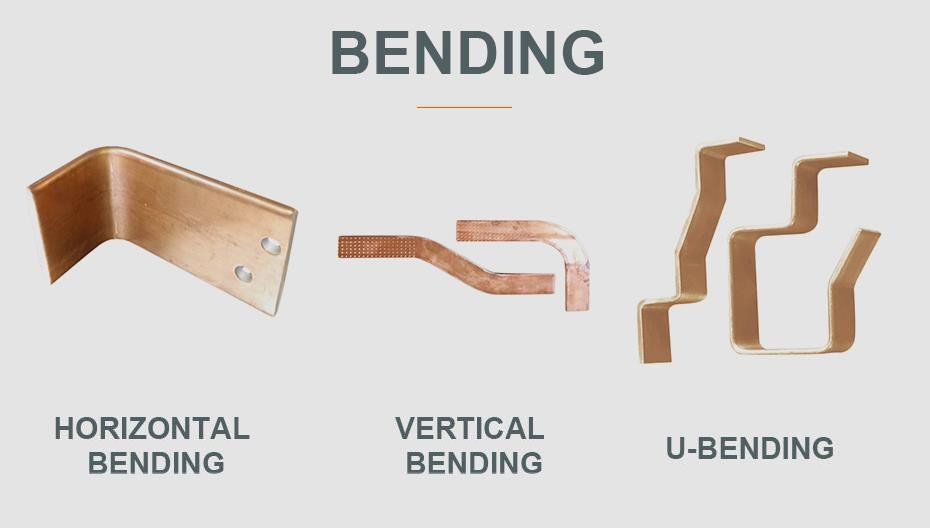

3. The Bending Unit adopts a horizontal bending structure. By simply changing moulds, you can complete flat bending or vertical bending tasks effortlessly.

4. A variety of processing functions such as embossing, flattening, twisting, and crimping of cable ends can be achieved by changing the specific moulds, making it one of our most versatile 3-in-1 busbar processing machines available.

5. The machine is equipped with four heavy-duty castors, so it is easy to be moved anywhere within your workshop or site.

6. Different moulds or tools can be installed according to user requirements to complete special shape processing for custom switchgear projects.

Product Details Display

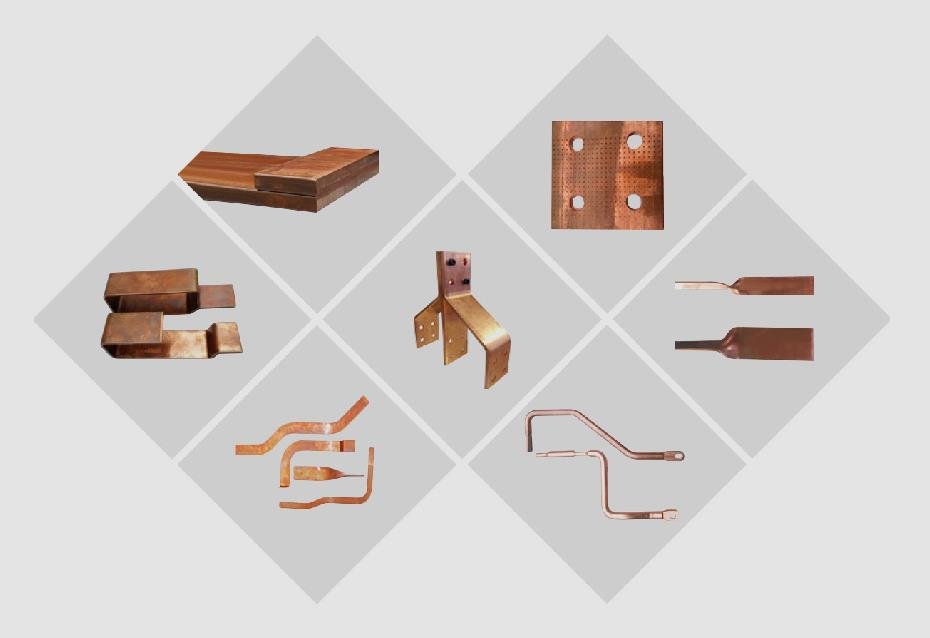

Processing Capabilities

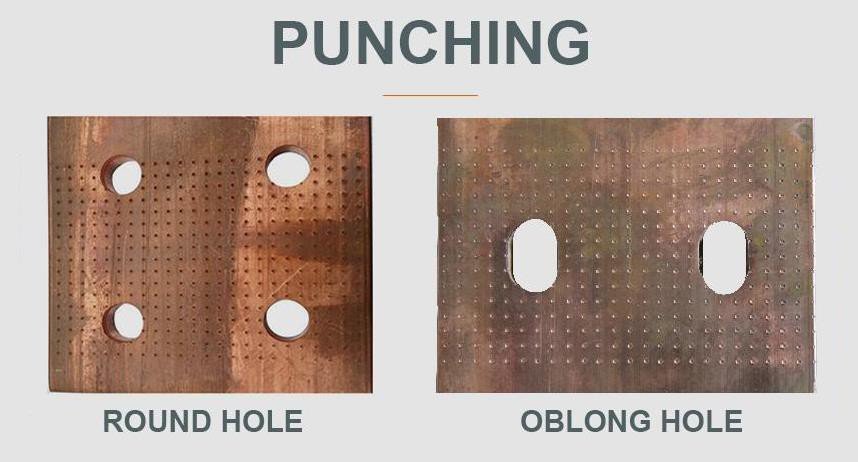

Punching Samples

It can punch round holes and oblong holes with the dedicated punching unit.

Shearing Samples

The shearing unit adopts a vertical shearing mode, flexible and convenient to operate. The interface of the busbar is flat, with no waste, no burrs, and no droop.

Bending Samples

The bending unit adopts a closed integral frame structure. It can perform flat bending, horizontal bending, vertical bending, and U-bending.

Other Processing Samples

Our Factory

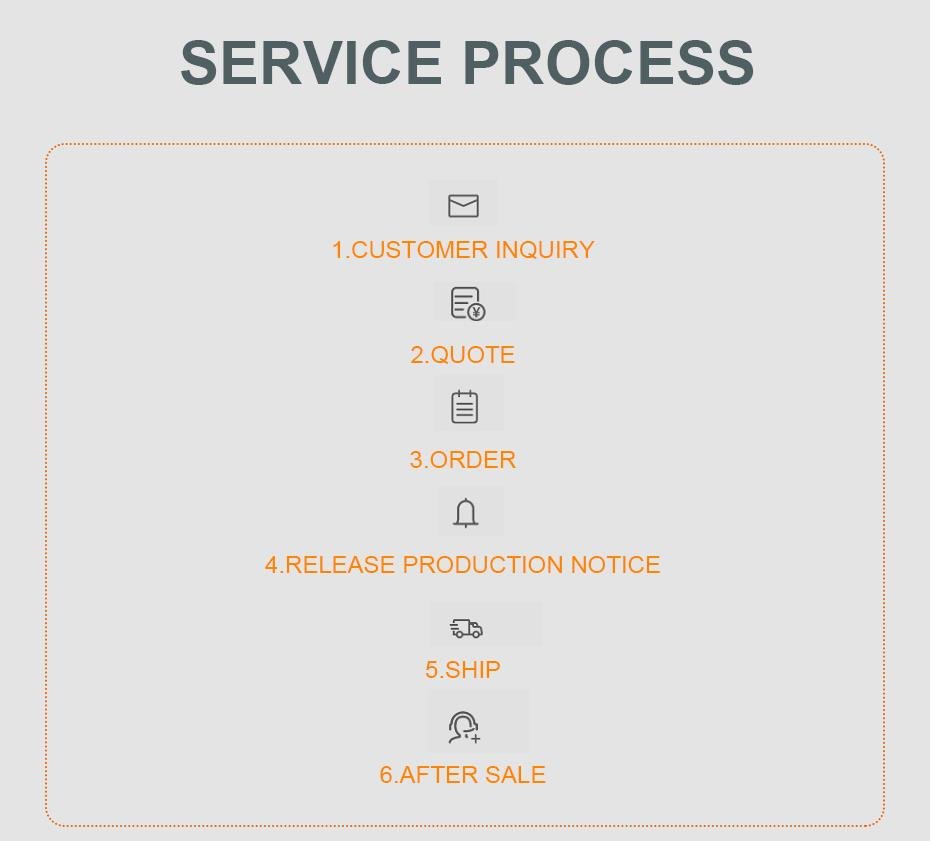

Our Service

Customer inquiry - Quote - Order - Release production notice - Ship - After-sales support

Our post-sales support engineers will also conduct regular return visits to listen to your valuable feedback and continuously improve product quality for the global market.

Package & Delivery

We use waterproof plastic film wrapped inside and sturdy wooden cases outside to ensure safe delivery to Australian ports.

Our Clients

LTMC Company mainly deals in various types of busbar processing equipment. Its performance is excellent, and it is sold well in more than 100 countries around the world, including the United States, Britain, Germany, Russia, Canada, Australia, New Zealand, and beyond. If you are looking for a premium manual copper & aluminium busbar processor, the 303U-3-C is your ideal choice.

Hot Tags: three unit busbar processing machine with manual control 303U-3-C, Australia, switchboard tools, copper busbar bender, hydraulic busbar machine, price

LT Busbar Machine Videos:

303U-3-C Manual 3-in-1 Hydraulic Busbar Machine FAQ

This FAQ covers common questions regarding the 303U-3-C busbar processing machine, designed to integrate punching, shearing, and bending for the Australian market.

Q1: What materials can the 303U-3-C process?

A1: The machine is designed for processing both copper and aluminium busbars of various specifications commonly used in switchboards.

Q2: What are the maximum processing dimensions?

A2: It handles busbars with a maximum thickness of 12mm and a maximum width of 150mm for all operations (punching, shearing, and bending).

Q3: How is the punching unit designed?

A3: The punching unit features a six-mode turnplate (turntable) in a tooth shape. This design reduces the need for frequent die changes, ensuring efficient workflow.

Q4: What type of shearing does the machine use?

A4: The shearing unit adopts a vertical flat blade cutting mode. This produces a smooth, burr-free interface with zero waste, essential for quality electrical connections.

Q5: Can the machine perform different bending operations?

A5: Yes, the bending unit supports flat bending, horizontal bending, vertical bending, and U-bending by simply changing the moulds.

Q6: Are there additional processing functions?

A6: By using specialized moulds or tools, the machine can also perform embossing, flattening, twisting, and cable end crimping.

Q7: Is the machine portable for site work?

A7: Yes, the 303U-3-C is equipped with four heavy-duty castors, making it easy to maneuver in workshops or on large construction sites.

Q8: What power supply does it require?

A8: It operates on a 1×4KW motor. We can configure the voltage to match local Australian standards (e.g., 415V/240V) upon request.

Q9: What are the dimensions and weight?

A9: Table size: 1650×1050mm; Overall dimensions: 1720×1220×1220mm; Total weight: 1220kg.

Q10: Who is this machine suitable for?

A10: It is perfect for switchboard manufacturers, electrical workshops, power distribution plant maintenance, and onsite fit-out contractors.

Q11: What support do you offer?

A11: LTMC provides comprehensive post-sales service, including installation guidance, operation training, and ongoing support to ensure your equipment runs smoothly.

Australian Industry Hot Tags & Keywords:

303U-3-C manual busbar machine, hydraulic busbar bender Australia, copper busbar punching tool, aluminium busbar shearing machine, switchboard fabrication equipment, electrical fit-out tools, busbar processing station, non-cnc busbar machine, 3-in-1 busbar worker, hydraulic hole puncher for copper, busbar bending dies, mobile electrical workshop, busbar machine supplier Sydney, busbar machine Melbourne, power distribution cabinet tools, copper bar cutting machine, manual hydraulic puncher, electrical contractor machinery, busbar bending radius, switchgear assembly tools, busbar fabrication center, heavy duty busbar bender, multi-function busbar processor, LTMC busbar machinery, cost-effective busbar machine.